During last week's Expeditionary Warfare Conference in Norfolk, I discussed the versatility and impressive capabilities that the Expeditionary Sea Base (ESB) platform are going to bring to our Fleet. As USNS Lewis B. Puller, the first of the ESBs, recently completed Initial Operating Test & Evaluation (IOT&E), the Navy is one step closer to augmenting our current force with the enhanced capabilities of this platform.

A significant part of the shipbuilding process are many first-of-class Post Delivery Test and Trials milestones and IOT&E, which must be completed prior to handing a ship over to the fleet. Over the past 10 months, the Navy’s first-of-class Expeditionary Sea Base, USNS Lewis B. Puller (T-ESB 3), has demonstrated exceptional capabilities and inherent flexibility in a series of in-port and at-sea events at Naval Operating Base Norfolk, Va. and the Virginia Capes Operating Area.

These events included:

· A demonstration of the Underway Replenishment Fueling at Sea system

· Launch and recovery of a 7m and 11m Rigid Hull Inflatable Boat (RHIB)

· Several Cybersecurity-related events

Throughout the course of Post Delivery Test and Trials, T-ESB 3 also conducted various Airborne Mine Countermeasures simulated missions, which included launch and recovery of:

· Mk-105 magnetic influence mine sweeping sled

· AN/AQS-24A mine hunting sonar system

· AN/ASQ-232 Airborne Mine Neutralization System

· and the Mk-103 mechanical mine, Mk-104 acoustic mine and the AN/SPU-1W magnetic mine sweeping systems.

The test period concluded in August with a final event required for all new construction ships to complete IOT&E. The test, led by Commander, Operational Test and Evaluation Force and observed by Director, Operational Test and Evaluation, was designed to demonstrate the ship’s full operational capabilities and determine the operational effectiveness and suitability of the platform. The ship will now prepare for a Post Shakedown Availability, follow-on crew training, and testing of additional capabilities installed to support Special Operations Forces, which will take place through the spring of 2017.

The ESB is optimized to support a variety of maritime-based missions and is designed around four core capabilities: aviation facilities, berthing, equipment staging support, and command and control assets. ESBs can also be enhanced to meet Special Operation Force missions through increased communications, aviation, and unmanned aircraft system support.

The ship has an aviation hangar and flight deck that includes four operating spots capable of landing MH-53E equivalent helicopters, as well as accommodations, work spaces, and ordnance storage for embarked force, enhanced command, control, communications, computers, and intelligence capabilities to support embarked force mission planning and execution, and reconfigurable mission deck area to store embarked force equipment to include mine sleds, rigid hull inflatable boats, and the Combatant Craft Assault.

Watch a video of ESB 3 operations here: .

|

| Figure 1: USNS Lewis B. Puller (T-ESB 3) was built by General Dynamics National Steel and Shipbuilding Company (NASSCO) in San Diego, California and delivered to the Navy in June 2015. After delivery, T-ESB 3 traveled around South America via the Strait of Magellan, arriving at Naval Operating Base, Norfolk, Va. in October 2015.

|

|

|

| Figure 2: The Post Delivery Test and Trials period began with the demonstration and certification of USNS Lewis B. Puller (T-ESB 3) for Underway Replenishment, Fueling At Sea. T-ESB 3 receives a double probe fuel STREAM rig from the fast combat support ship USNS Arctic (T-AOE 8) in the Virginia Capes Operating Area. |

|

|

|

|

| Figure 3: USNS Lewis B. Puller (T-ESB 3) is capable of onloading, storing, and offloading Airborne Mine Countermeasures equipment up to 10 metric tons. Larger gear weighing more than 10 MT can be on-loaded with the support of shore side Material Handling Equipment. |

|

|

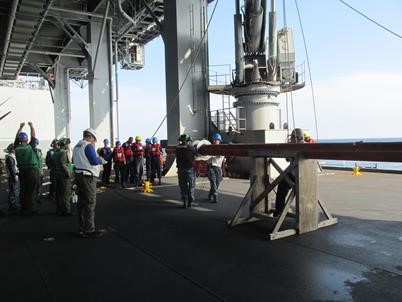

| Figure 4: The crew of the USNS Lewis B. Puller (T-ESB 3) demonstrates launch and recovery of an 11m Rigid Hull Inflatable Boat. The ships Military Crew provides Material Handling Equipment operators to maneuver the craft on the T-ESB 3 mission deck and line handlers to control the boat while being maneuvered by the ship’s mission deck crane. Military Sealift Command provides Civilian Mariner crane operators and deck safety officer for this evolution. |

|

|

| Figure 5: USNS Lewis B. Puller (T-ESB 3) crew demonstrates launch and recovery of a Airborne Mine Countermeasures 7m RHIB. Three Airborne Mine Countermeasures RHIBs are launched during Airborne Mine Countermeasures helicopter towing operations. T-ESB 3 is capable of launching and recovering boats and sleds up to 25,000 lbs. through NATO Sea State 3 (SS3). |

|

|

| Figure 6: Dynamic Interface testing is conducted to evaluate the USNS Lewis B. Puller (T-ESB 3) ship aviation facilities in support of an Aviation Certification for day and night launch and recovery operations, aircraft servicing and hangaring. Additional purposes of DI are to establish and expand operational envelopes for the MH-53E, conduct a Vertical Replenishment demonstration in support of operational requirements and certify flight deck crew qualifications.

|

|

|

| Figure 7: USNS Lewis B. Puller (T-ESB 3) demonstrates the Vertical Replenishment with two aircraft: MH-53E and MH-60S. The full Vertical Replenishment evolution consists of an approach, a hover over the designated area for a load hookup, a departure into one lap around the pattern with the load attached, a hover over the designated area for load drop-off and a departure. Tanks filled with sea water simulated actual loads.

|

|

|

| Figure 8: USNS Lewis B. Puller (T-ESB 3) employs a flight deck for helicopter operations. T-ESB 3 is able to carry four MH-53E helicopters or five Twenty Foot Equivalent Unit Military Vans and still have room to maneuver and store other equipment. |

|

|

| Figure 9: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can support the configuration, installation, removal and reconfiguration of the Mk‑103 mechanical minesweeping system. During deployment, the Mk-103 system is stored on the mission deck before being configured and brought up to the flight deck via the ship’s organic aft knuckle boom crane. Once on the flight deck, the ship’s Material Handling Equipment maneuver the equipment to the MH-53E helicopter where it is installed to be transported to the mine field and lowered to the water to conduct its mission. The Mk-103 uses mechanical cutters to sever tethers connecting mines to the sea floor allowing them to float to the surface where they can be neutralized.

|

|

|

| Figure 10: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can support the configuration, installation, removal and reconfiguration of the AN/AQS-24A mine hunting sonar system. The AN/AQS-24A utilizes a special workshop consisting of three Military Vans that connect together to form a large work space. They are secured on the flight deck allowing calibration of specialized equipment to take place prior to loading into the MH-53E to conduct its mission.

|

|

|

| Figure 11: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can support the configuration, installation, removal and reconfiguration of the Mk-104 acoustic minesweeping system. During deployment, the Mk-104 system is stored on the mission deck before being configured and brought up to the flight deck via the ship’s organic aft knuckle boom crane. Once on the flight deck, the ship’s Material Handling Equipment maneuver the equipment to the MH-53E helicopter where it is installed to be transported to the mine field and lowered to the water to conduct its mission.

|

|

|

| Figure 12: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can support the configuration, installation, removal and reconfiguration of the Airborne Mine Neutralization System SEAFOX. The SEAFOX is a remotely operated vehicle designed to locate and attach disposal charges to mines. The T-ESB 3 provides two SEAFOX magazines with a capacity to hold 50 rounds each. Special ordnance handling equipment is used to transport the explosive rounds from the SEAFOX magazines to the helicopter where it is installed and integrated with the SEAFOX control system console also loaded into the helicopter.

|

|

|

| Figure 13: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can launch and recover the Mk-105 magnetic minesweeping sled. The sled is lowered to the water prior to being attached to the MH-53E helicopter. Once in the water, Airborne Mine Countermeasures 7m Rigid Hull Inflatable Boats tow the sled away from the ship to where it’s connected with the MH-53E for its towing mission. The sled, which planes over the water on retractable hydrofoils, creates a magnetic signature to identify specific mine threats.

|

|

|

| Figure 14: USNS Lewis B. Puller (T-ESB 3) demonstrates that the ship can launch and recover the AN/SPU-1W Magnetic Orange Pipe minesweeping system. The Magnetic Orange Pipe, which is magnetized on deck of the T-ESB prior to deployment, is used to influence magnetic mines in littoral waters and rivers. It is lowered to the water independent of being attached to the MH-53E helicopter. Once in the water, the Airborne Mine Countermeasures 7m Rigid Hull Inflatable Boats tow the system away from the ship where it’s connected with the MH-53E for its towing mission.

|

|

| Figure 15: USNS Lewis B. Puller (T-ESB 3) will enter a Post Shakedown Availability in Q1 FY17 and is preparing for initial deployment.

|

Photos above by U.S. Navy