Missile Warheads

January 3, 2018

By: William E. Elliott Jr.

Special Guest Writer

Ordnance development is a field of experience, training and mentorship. Long before the modern computer era, the effects of explosive reactions were investigated using classical mechanics and a great deal of trial and error. Concepts were built, tested and instrumentation was key (how do you see inside a detonation?). With deep experience in projectiles, Dahlgren set out to develop its first anti-ship missile warhead. The ordnance team, which fielded Bullpup in 1959, included a young engineer named Charlie Cooper. By the 70’s, when I arrived as a COOP, he was heading up a division of people developing ordnance. The Branch head for the warhead technology Branch was Danny Brunson, who cut his teeth on the development of the HI-FRAG 5-inch projectile. The head of the Warhead Development Branch was Clyde Johnson, who co-authored the warhead handbook with John Mosely in 1965 (it’s still a pretty good reference, now unclassified). This was the casual level of expertise that Dahlgren could bring to bear related to ordnance. The Bullpup Warhead was successful and Bullpup A and B Warheads were employed in PENGUIN and TOMAHAWK missiles respectively. This led the way for Dahlgren into missile warhead development efforts.

As a young engineer, my first introduction to missile warheads was the development of the STANDARD Missile (SM) Mark (Mk) 90 Warhead in the mid-1970s. Mk 90 was a quick reaction program to develop a fragmenting warhead design, providing better lethality against surface targets. Working with Paul Bolt and Dick Ramer, the program conducted static arena tests at Pumpkin Neck and dynamic arena tests at White Sands Missile Range where a missile was flown into an arena of witness plates. I was assigned to develop a computer program characterizing the fragment data used to validate its lethality versus the targets of interest. The HP 9838 desktop, with its 16K of memory and 32 character LED display, was a drastic improvement over punch cards and walking across base to the mainframe computer. This let me work with senior engineers and scientist. They may not have been computer literate yet, but they had the deep experience from years of work in the field. (people like Dr. Mock, Dr. Holt, Sam Waggener and many others).

|

| Warhead Branch Personnel |

|

| Dave Smith and Bill Elliott discussing Mk 115 Warhead Design |

|

| Mk 115 Warhead Design Team |

|

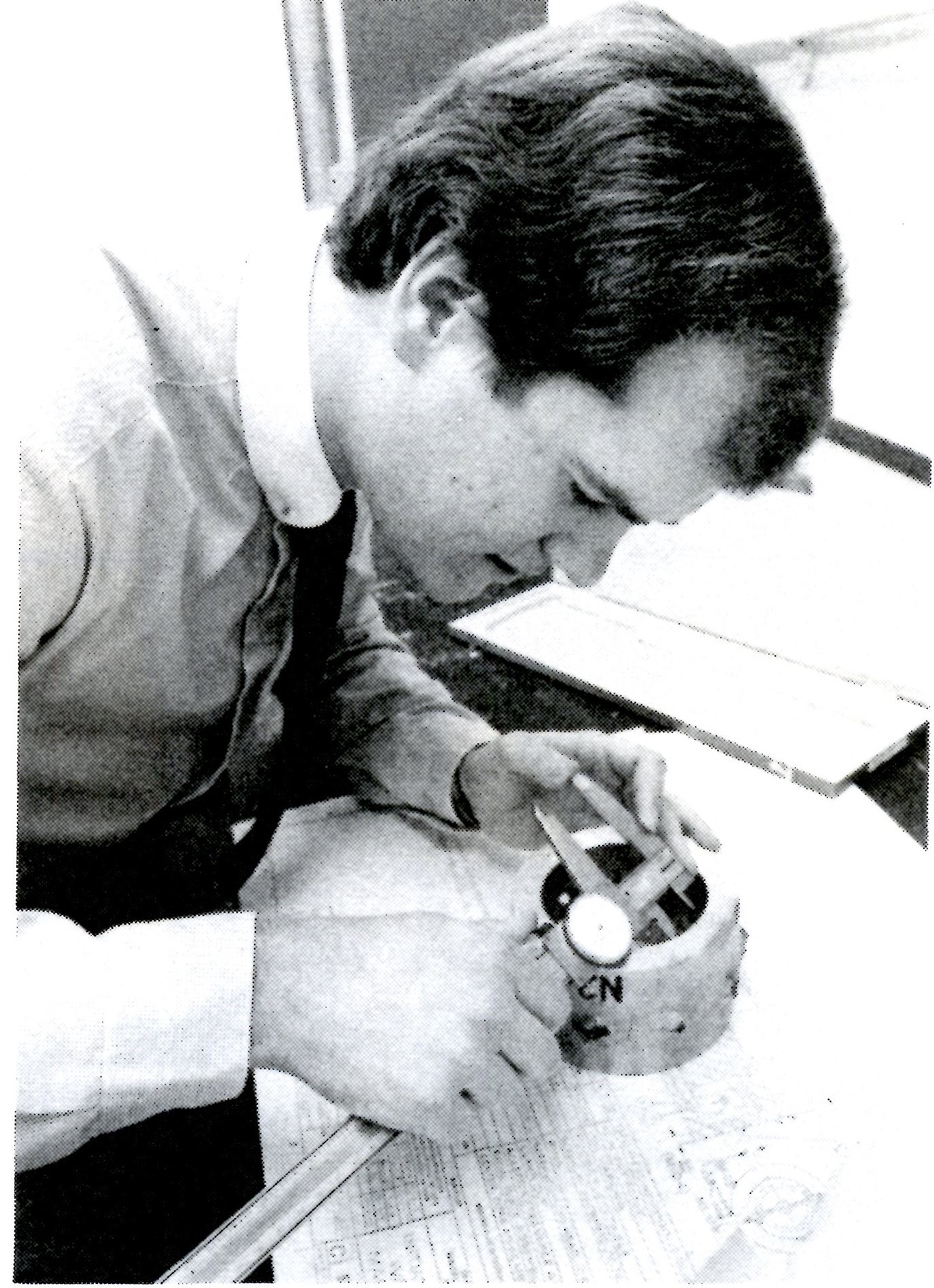

Pat Spahn inspecting Mk 18

Multipoint Initiator |

|

| Flash X-Ray Test Film |

|

| Fred Landman, Henry Goerlitz, and Keith Slocum inspecting a Mk 115 Warhead. |

|

| John Moseley, James Tate, Joe Powell aligning a Mk 115 Warhead for an arena test. |

|

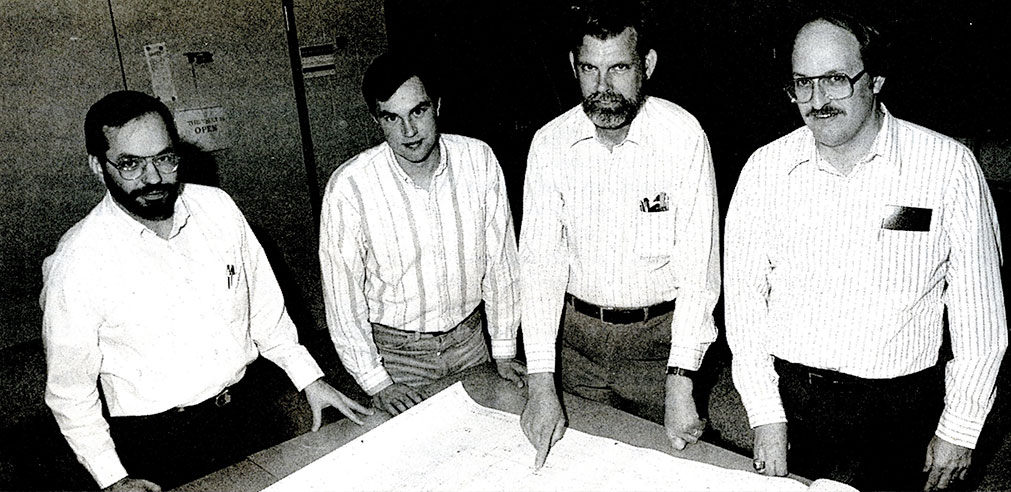

| Mk 125 Warhead Design Team, L to R: Bill Elliott, Charles Garnett, Bob Dibble, Bill Henderson. |

|

Mk 125 Warhead Team, L to R: Charles Garnett, George Clotfelter, Larry Wicks, Bill Elliott

|

|

| Mk 125 Warhead Development Team. Front Row: Tracey Rollins, Roi Voelker, Charlie Smith, Charles Garnett. Middle Row: Franklin Brown, Larry Wicks, Kenny King, Fred Landman, George Clotfelter, Benny Vento. Back Row: Don Ammerman, Dr. Tom Goswick, Joe Powell, Donna Crabtree, Bob Dibble |

|

| Harry (left) and Elgin (right) had lots of fun balancing ordnance section requirements and schedule for their respective programs. |

In the 70s and 80s missiles like PHOENIX, SPARROW, and STANDARD Missile utilized CR warheads, designed to defeat aircraft. As the warhead detonated a continuous rod of metal would expand impacting the aircraft and slicing off wings. These warheads required a great deal of material expertise. The welded rods had to expand without breaking apart. Dahlgren played a significant role in optimizing CR warheads utilizing the A&P lab (the Armor and Projectile Lab). The A&P Lab maintained a world class set of expertise in material science and testing.

Unfortunately, Weapons development is a series of moves and counter moves as the threat evolves. The elegant CR warheads had reached the end of their utility. The newer anti-ship missiles being developed were small, fast, hard to detect and engage, and the continuous rod warhead did not have the performance characteristics needed to defeat these anti-ship missiles. So, a new family of warhead designs was introduced. These new warheads used controlled fragmentation techniques, advanced explosives, and new initiation systems that provided an increased probability of hitting the target. In parallel with these ordnance section improvements, the missile designs were also updated with enhanced guidance solutions, improved Target Detection Devices, improved missile dynamics and flight profiles to increase their system effectiveness versus these anti-ship missiles.

Al Hales lead the effort to show the missile program offices that Continuous Rod (CR) warheads needed to be replaced with newer controlled fragmentation designs. He was very successful and by the late 70’s, there were three full scale missile warhead development programs going on at Dahlgren. Tom Sweirk’s team developed a new SPARROW warhead, Tom Smith’s team developed one for PHOENIX, and Dave Smith lead the STANDARD Missile Warhead Team.

In 1976, STANDARD Missile started development of the Mk 115 focused-blast fragmentation warhead. The Mk 90 had just entered service a few years before, but the performance payoff for a warhead optimized for the newer air threats was too great to ignore. In fact, while the Mk 115 was originally developed for the SM-2 BLK II Missile it was later used in SM-2 BLK III and Blk Missiles. Early goals were to back fit nearly all missiles in the fleet with Mk 115 warheads. The new AEGIS Ticonderoga CG-47 class of ships had just been developed and warhead qualification and pilot production was expedited to support initial deployment of the CG-47.

The MK 115 Warhead design team was composed of Dave Smith, myself, Keith Slocum, and John Moseley. Our sister lab at White Oak Maryland provided initiation expertise via Bob Durrell and Pat Spahn. As the MK 115 warhead test engineer I was responsible for validating warhead performance and coordinating the various safety tests required to deliver a warhead to the fleet. A new testing technique, called flash x-ray, was developed that allowed us to accurately characterize warhead fragment performance by capturing a photo of the fragments in flight. Desktop computers were still new to the office environment and you had to write your own programs to solve engineering problems. Sam Waggener along with the help of Travis Shelton’s team had developed the flash x-ray methodology but Sam was computing results by hand. He would lay out the radiographs on a large table and draw lines between the fragments. A high-tech version of the connect-the-dots. A new coop student, Charles Garnett, was introduced to us and developed the software program to automate this analysis. Charles was given the new HP 9845 computer to work with (in 1981, 64K of memory and a computer monitor were unheard of on a desk machine). Like my earlier efforts, Charles learned his craft coding up information from senior scientist.

His program was a success and allowed us to provide very detailed warhead frag data used to validate warhead performance. Working with Joe Powell as my test engineer, full scale tests were also conducted at Pumpkin Neck to further validate warhead performance. After the design is tested and validated it is then required to meet a series of safety tests. This is accomplished at the Pumpkin Neck facility where a series of tests such as temperature and humidity, various vibration tests, fast cook-off, bullet impact, 40-foot drop are conducted and the warhead must pass. The program was a success as mentioned earlier and delivered to fleet in time to support the CG 47 deployment.

In parallel with the Mk 115 development, Al Hales had started looking at warhead designs optimized not just for modern anti-ship missiles, but optimized to take advantage of the new capabilities of the AEGIS system. Charles Garnett, my young COOP programmer was teamed with Paul Bolt, (one of the designers of the Mk 90) to generate performance models for study. These efforts grew into the Mk 125 warhead concepts. By 1986, Walter Hoye had taken over the Warheads Branch and I was the program manager for the Mk 115, completing the qualification tests and moving it into production. Wanting to get back into development work, I lead the newly stood up Mk 125 warhead team. The initial design team was small, Charles Garnett and Bill Henderson and later adding Bob Dibble. The Mk 125 design incorporated a state-of-the-art controlled fragmentation technique, initiation technology from the Department of Energy, and the latest development in high energy explosives. The MK 125 Warhead provided high velocity focused fragments towards the target increasing our probability of engaging and destroying the target. This warhead is utilized in the SM-2 BLK IIIA and SM-2 BLK IV Missiles. Selected to go into the SM-6 the Mk 125 warhead has been in service since 1991 and will easily take us into another decade.

Warhead development requires more than just a good core design team. Expertise is drawn from all over Dahlgren in order to successfully test, qualify, and approve for fleet delivery. Personnel such as Dr. Tom Goswick, Tom Wasmund, and Chuck Ellington developed threat models and estimated the lethality of the warhead versus the targets. System safety was the primary responsibility of such personnel as Don Ammerman and Gary Friedman. They ensured safe operation and obtained approval of Weapons Safety Evaluation Review Board to allow warhead introduction to the fleet. During development Kenny King and Tracey Rollins provided detailed computer aided design drawings to be used by contractors to produce hardware. A new state of the art initiator concept was developed that had increased reliability and improved initiator to explosive performance using the expertise of Brad Hanna, Tim Spivak, and Ed Lustig from the White Oak laboratory.

During this era, SM Ordnance Sections were government furnished equipment. The ordnance section consisted of the warhead, the Safe-Arm device and the target Detection Device (TDD). The development and delivery of the ordnance section required a national SM community effort. Our Ordnance section development team, led by the NAVSEA program office, had to interface with expertise from various Navy labs at China Lake for TDD and Safety Arming Device designs, Port Hueneme for logistics, Naval Weapon Stations Yorktown and Indian Head for explosive loading, the TDD engineers at Motorola, Scottsdale, AZ and the missile prime contractors of General Dynamics, Pomona CA, later Hughes and now Raytheon at Tucson, AZ. The new Mk 125 warhead was being developed for the both the SM-2 Blk IIIA (Mk 132 Ordnance Section) and SM-2 Blk IV (Mk 133 Ordnance Section) missiles during the same time frame. Our NAVSEA program managers of Elgin Werback (Blk IIIA) and Harry Farley (Blk IV) worked closely together to ensure their respective ordnance section development efforts met their required missile specifications and interfaces. We worked hard but we also enjoyed what we accomplished and we liked to capture some of the program management struggles as the program was executed. The Dahlgren warhead team played a key role in the Ordnance Section development providing expertise in systems engineering, the development of various specifications, and participated in various preliminary and critical design reviews. Local technical contract support from Janet Clift and Robert Schroder was also vital towards the generation and delivery of various warhead and ordnance section specifications required before the warhead could be delivered to the fleet.

STANDARD Missile has had 4 generations of warheads over its service life. 3 of those were developed and fielded by the Naval Surface Warfare center at Dahlgren. But all good development teams are made up of mixture of old and young, experience and youthful passion. I had the good fortune to be a part of all 3 warheads (MK 90, Mk 115 and Mk 125) at various stages in my career. I had the opportunity to work with an excellent team of Dahlgren engineers, engineers from other Navy labs and various contractors, and the NAVSEA program office. It was an exciting time at Dahlgren as the Warheads Branch developed and delivered warheads to the fleet.