CRANE, Ind. –

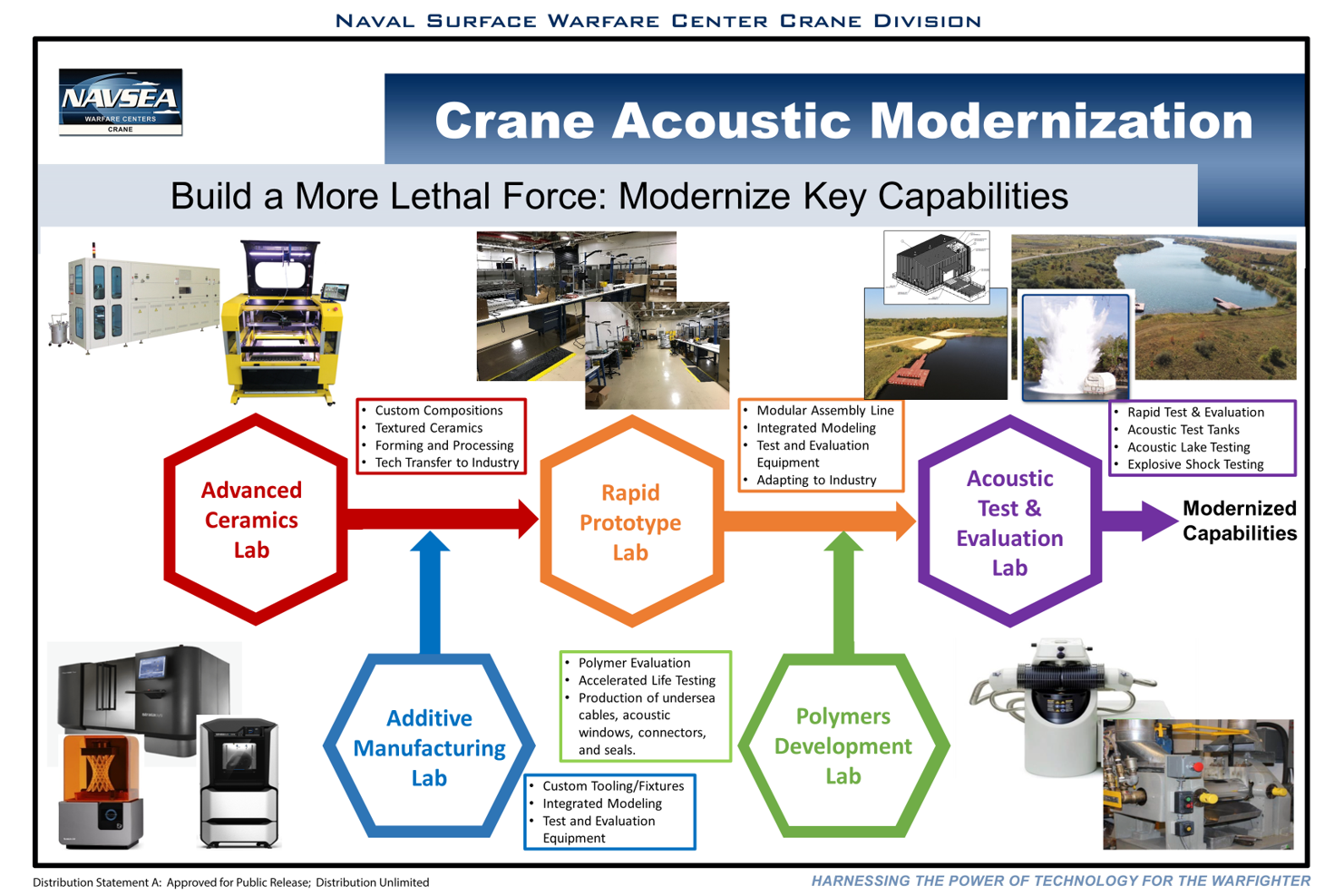

Naval Surface Warfare Center, Crane Division (NSWC Crane) has reached a milestone in its delivery of 50-thousand TR-343 transducers to the US Navy Fleet over the past decade. As an offshoot of the technical lessons learned in this project NSWC Crane along with Naval Undersea Warfare Center, Newport Division (NUWC Newport) and PMS 401 has initiated a modernization effort to meet the needs of rapidly evolving threats at sea.

Theodore Ioannides, the Principle Assistant Program Manager of PMS 4013 says, these sonar modernization efforts are imperative for the Navy and to reduce threats from peer military adversaries.

“Without the advancement of the TR-343 transducer, we could be very stagnant on our capability,” says Ioannides. “Ultimately, our ships could be vulnerable.”

“Without the advancement of the TR-343 transducer, we could be very stagnant on our capability,” says Ioannides. “Ultimately, our ships could be vulnerable.”

The TR-343 is a major component of the AN/SQS-53C which is the hull mounted array for the AN/SQQ-89(V) weapons system with Anti-Submarine (ASW) capability. This system helps provide the ‘eyes and ears’ to Navy ships; the weapons system is a fully integrated surface ship undersea warfare combat system with the capability to search, detect, classify, localize, and engage submarines in the ocean.

David Bartlett, Chief Engineer for Undersea Sensors at NSWC Crane, says this milestone is significant to the Fleet.

“It means that ships can get underway,” says Bartlett. “NSWC Crane has been one of the largest providers of Transducers and Hydrophones to the Navy for some time. In fact, we have been the only provider of TR-343s for the past nine years. Surpassing the 50K mark simply means that we have had to pick up the slack and provide units so that our surface ships can complete their mission. In that time, we have not missed a delivery of any kind despite many obstacles including seriously reduced supply base.”

The transducer modernization effort has been a collaborative effort between Submarine Acoustic Systems Program Office PMS 401, NUWC Newport, Penn State Applied Research Laboratory (ARL), NSWC Crane, and several contractors. Bartlett says the expertise comes together from the different organizations to collaborate as a team.

“NSWC Crane is a main provider of support for the transducer technology,” says Bartlett. “NUWC Newport is the Technical Design Agent and provides system level performance parameters and NSWC Crane provides sensor level and component level expertise. Together, we provide the Program Office with a thorough understanding of the current conditions needed to modernize acoustic sensors. We repair and do new construction for this particular system. A single transducer feeds into larger systems onboard ships. Information is gathered from the sensors and used by many systems. Making changes to a sensor makes changes to everything. It takes a team effort to understand the ripple effect. It’s taken hard work and dedication of the team to get things done.”

Bartlett explains how the nature of threats has changed as technology has evolved.

“Military tech hasn’t progressed as rapidly as the threats,” says Bartlett. “Today’s undersea threats have changed significantly in the past ten years with the advent of quieter adversaries on Unmanned Underwater Vehicles (UUVs) and smarter/faster munitions, it means that we need to be able to detect and prosecute targets that much faster and farther away. 50K transducers simply means that Crane has the expertise to build undersea sensors. Modernization is about creating an innovative inclusive environment where we can collaborate to evaluate and develop tomorrow’s state of the art acoustic sensor technology to an acquirable state today – while staying ahead of rapidly developing real world undersea threats. Our adversaries are building harder and faster munitions and quieter submarine vessels. In order to maintain a technological edge, we needed to step it up.”

Abdul-Hadi Hassan, the Modernization Lead at PMS 4013, says the pace that they have been able to implement the new technology is key to the success of the modernization effort.

“We are having to rapidly innovate,” says Hassan. “We are taking ideas, concepts, and technology out of the lab and incorporating them at a rapid pace. We’ve been evaluating and fielding this as fast as possible.”

Bartlett says this modernization effort is significant in several ways.

“Our world in undersea systems has changed dramatically in the last 10-15 years,” says Bartlett. “Obstacles such as reduced budgets and supply chain issues for sonar technology has made it difficult to improve the situation. Additionally, like many other current acoustic sensors, the TR-343 is based on 1960’s era piezo-electric ceramics technology. At that time, the Navy was the main customer. That is not the case today. There’s a lot of changes in the world that have taken place since then. Current technology hasn’t evolved; we still rely on Lead Zirconate Titanate (PZT) ceramics for our needs.”

Bartlett explains that part of the issue is the supply industry is shrinking, while the commercial market has grown.

“The market has grown in numerous areas, such as the automotive and medical industry,” says Bartlett. “There are many industries using newer technology, but the military is a small fraction of the market demand and our devices are larger in scale and more costly to build. A 2018 Health Assessment showed that the Navy is now less than 1% by volume and less than 6% by cost of that same market. Consequently, Independent Research and Development (IRAD) dollars are not going toward fixing the Navy’s acoustic sensing issues; it is low volume, high cost. Those dollars are going toward the commercial market space, not the Navy.”

Ioannides says the sonar technology landscape has changed drastically in recent years.

“The industrial base is shrinking drastically,” says Ioannides. “The number of contractors has gone down significantly in the last 15 years, and the old way of doing business took 20 years to go through a process. Crane has stepped up to the requirement and has met the need at full force. In the last five years, the automotive industry has had an exponential rise in its need for piezo ceramic devices. The capability to produce ceramics is a challenge because we aren’t expanding raw materials—more people are sharing them.”

Bartlett says the next steps for the modernization effort will show utility.

“It’s important for the sonar community to know we need to change ‘business as usual,’” says Bartlett. “We need to provide a collaborative environment and hone in on our technology. It doesn’t have to take 20 years and millions of dollars. Moving forward, it’s all about getting the technology out of the lab, into the mission, and demonstrating utility. These improved capabilities for breaking down barriers to technology insertion will be operational this next calendar year. The Navy is coming together to solve some significant undersea sensor issues that will impact both today’s Navy as well as tomorrow’s. Together with the team, we’ll push toward multiple pilot programs such as advanced ceramics in order to meet the capability needed for today. It can be scalable and manufactured at reasonable cost.”

Along with PMS 4013 and Penn State ARL, there are multiple pilot programs going on this year designed to demonstrate capability improvements offered by textured ceramics and to improve the Manufacturing Readiness Levels (including scalability and costs). Teams are also starting to re-engage commercial vendors to enlist their support.

Ioannides says what they have worked through is a process that can be applied for much broader impact and increasing military readiness of the fleet.

“What we’re talking about is one transducer—but we have hundreds we are targeting in the future,” says Ioannides. “The process works; we need to incorporate that into as many transducers as possible.”

About NSWC Crane

NSWC Crane is a naval laboratory and a field activity of Naval Sea Systems Command (NAVSEA) with mission areas in Expeditionary Warfare, Strategic Missions and Electronic Warfare. The warfare center is responsible for multi-domain, multi- spectral, full life cycle support of technologies and systems enhancing capability to today's Warfighter.