Download the PDF file

Background

The following contains a brief

description of isolation technologies used for radiation hardened integrated

circuits. The technologies mentioned are junction isolation, Dielectric

Isolation (DI), Silicon on Sapphire (SOS), and Silicon on Insulator (SOI). The

report is intended to be informational. The results of Internet searches and

interviews with Code 605 personnel involved with the Strategic Systems Program

were the primary sources of information. The Strategic Systems Program relies

on these non conventional isolation techniques for radiation hardened integrated

circuits.

Executive Summary

For over 40 years

junction isolation has been the primary technology used to isolate the

individual components on integrated circuits. Early alternate technologies such

as DI, SOI, and SOS were driven by their ability to tolerate radiation. There

are relatively few applications for radiation hardened parts therefore the

demand for DI, SOI, and SOS has been quite small. DI, SOI, and SOS wafers

accounted for a very small portion of the worldwide Silicon wafer production

prior to 2000. In the late 90’s the demand for high speed VLSI Integrated

Circuits was pushing junction isolation to its technological limits. The

performance advantages of thin film Silicon on Insulator (SOI) integrated

circuits brought about improvements in SOI. This resulted in an increased

demand for SOI wafers. Semiconductor Equipment and Materials International

(SEMI) estimates that SOI wafer sales doubled to $405 million in 2005.1 Yet SEMI estimates

that was less than 5% of Silicon wafers sales worldwide. SEMI predicts that

sales will reach $911 million by 2009. The worldwide demand for high

performance integrated circuits has produced a reliable source for a

commercially available radiation tolerant semiconductor manufacturing

process.

Introduction

Monolithic Integrated Circuits

(ICs) have traditionally utilized junction isolation as a means of electrically

isolating individual active and passive devices on the IC. Individual devices

are diffused into a substrate. A reversed biased P-N junction between the

substrate and individual devices provides the isolation between devices. The

process is well established, reliable, and economical.

DI, SOI, and SOS make use of an

engineered wafer. The IC manufacturer buys a wafer that has been manufactured

with an insulating layer beneath the active Silicon. These wafers can be

engineered to replace the standard bulk Silicon wafers in a conventional

junction isolation IC manufacturing process. An IC isolated by a dielectric

such as Silicon Dioxide (SiO2) or Sapphire

(Al2O3) has advantages over its junction isolation

counterpart. Three of the main advantages are immunity to radiation, lower

leakage currents, and higher operating frequency all due to the elimination of

junction isolation.

Photocurrents generated by

ionizing radiation in junction isolation can impact an integrated circuit in

many ways. Photocurrents are reduced by dielectric isolation. The main benefit

of dielectric isolation is the elimination of LATCHUP (LATCHUP is the

inadvertent creation of a parasitic Thyristor structure in an Integrated

Circuit). A switch to DI, SOI, or SOS can dramatically improve an IC’s

immunity to Prompt Dose radiation or Single Event Effect radiation. There are

many factors to consider when designing a radiation tolerant integrated

circuit. Switching a process to DI, SOI, or SOS is not a guarantee that the IC

will be radiation tolerant. The dielectric that improves Prompt Dose and Single

Event response may trap charge and degrade the Total Dose response unless

additional processing steps are taken. Several processing and design techniques

must be utilized to guarantee a radiation tolerant IC. Some of these can also

be used to improve the radiation tolerance of junction isolation technologies.

Dielectric isolation doesn’t have

the leakage current to substrate that junction isolation does. The leakage

current of a reverse biased P-N junction increases with temperature. This can

limit the maximum operating temperature of IC’s utilizing junction

isolation.

Reversed biased P-N junctions

possess an inherent capacitance. This parasitic capacitance limits the

operating frequency of an IC. The parasitic capacitance of a dielectrically

isolated part is lower than that of one utilizing junction isolation. This

gives dielectric isolation a performance advantage versus its junction isolation

counterpart. It enables a dielectrically isolated part to operate at higher

frequencies and lower power. This performance advantage is currently the main

driver for commercial SOI technology.

Technologies

DI

Technically DI, SOS, and SOI are all dielectric isolation. In this

discussion DI refers to a specific isolation technique that is different from

SOI and SOS. DI processes, often referred to as poly DI, have been used for

over 30 years in radiation environments.

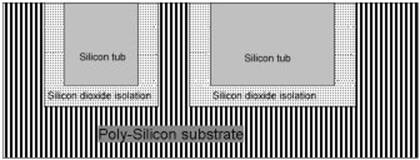

DI processing typically begins

with an N+ type wafer. An N type Epitaxial layer is grown on the wafer. Masked

N and P diffusions form islands for the individual devices. The individual

devices are isolated by etching moats around the islands. The moats extend down

to the N+ starting wafer. A thick oxide is grown that forms the isolation on

the sides and bottoms of the devices. A thick layer of Poly-Silicon is

deposited to fill in voids and add strength. The Poly-Silicon will be the

substrate for the finished device.

The N+ starting wafer is removed

by abrasive polishing. Modern DI processes use a final electrochemical etch

that automatically stops at the lower doped Epitaxial layer; this allows the

thickness of the final islands to be determined by the Epitaxial process. The

remaining dielectrically isolated islands can be processed into integrated

circuits.

Figure (1) is a simple diagram showing a cross section of a DI wafer. DI is a

mature process. It is well suited for high voltage applications (MOS Vgs

to150V, BJT BVceo to 35V). It is a relatively low frequency

technology due to lack of additional development. The process does not produce

a uniform thin film of Silicon needed for high performance integrated circuits.

Wafer warping has limited the size of the wafers to 4 inches. It is not certain

how long IC manufacturers will continue to produce DI.

Figure (1) Diagram of Dielectric

Isolation Cross Section

SOS

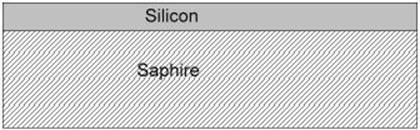

SOS refers to

Silicon on Sapphire. The active Silicon device is formed on an electrically

insulating crystalline Al2O3 (Sapphire) substrate. An

Epitaxial layer of Silicon is grown on a crystalline Sapphire wafer. Subsequent

Ion implantation and heat treatment produce a thin silicon film suitable for

high performance IC fabrication.

During IC fabrication islands of

Silicon are formed by patterned oxidation of the Silicon film. The islands of

Silicon are isolated laterally by Silicon Dioxide that extends to the Sapphire

substrate. Sapphire is one of the few insulating substrates that single crystal

Silicon can be grown on. Figure (2) is a diagram showing a cross section of an SOS wafer.

SOS technology has

been developing since the 1960s. In the beginning it was plagued by the lattice

unconformity between the crystalline Silicon and crystalline Sapphire. The

unconformity created lattice defects in the Silicon. Diffusion of Aluminum from

the Sapphire into the Silicon was also a problem. Improvements in technology

have made SOS more reliable and accelerated the development since the 1990’s.

SOS can have excellent Prompt Dose and Single Event Effect radiation immunity.

High quality passive components such as inductors can be constructed on it. An

additional advantage is that the translucent sapphire wafer allows for

implementation of high performance optical interconnect communication. This can

accomplished using Vertical Cavity Surface Emitting Lasers (VCSEL) and coupling

through the substrate. Flatness of Sapphire wafers is somewhat inferior to

Silicon wafers.2 This has

discouraged large area high integration circuits from being fabricated on

SOS.

Figure (2) Diagram of Silicon on

Sapphire Cross Section

SOI

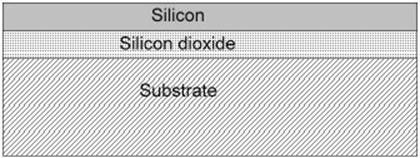

Technically

DI could be considered Silicon on Insulator (SOI). In this discussion SOI

refers to integrated circuits that consist of a thin film of single crystal

Silicon separated from the bulk substrate by a layer of insulating Silicon

dioxide. Several vendors, including IBM, National Semiconductor, Honeywell,

Advanced Micro Devices and Intel, are currently supporting SOI processes. The

performance of an SOI device relies on the ability to fabricate a thin film of

defect free single crystal Silicon. Currently there are two approaches that

have been widely used for manufacturing SOI starting wafers. One method is

known as Separation by Implanted Oxygen (SIMOX) and the other is wafer

bonding. Oxygen ions are implanted into Silicon to form the Silicon dioxide

layer in the SIMOX process. The energy and dose rate of the implant control the

depth and thickness of the oxide layer. The oxide layer forms after a high

temperature annealing. The annealing does not remove all of the lattice damage

from the implanted Oxygen. Silicon pipes from the active silicon layer through

the oxide to the substrate are also a problem. Current processes have reduced

defect levels to acceptable levels. Lateral devices fabricated on SIMOX wafers

are less affected by Silicon defects than vertical devices. SIMOX is well

suited for high performance low voltage CMOS integrated

circuits.

Figure (3) is a diagram showing a cross section of a SIMOX wafer. Patterned

local oxidation of the Silicon film during IC fabrication defines the lateral

isolation of the individual IC components.

Figure (3) Diagram of SIMOX Cross

Section

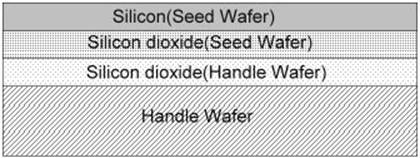

Wafer bonding avoids the damage

caused by implanted Oxygen. The oxidized surfaces of two Silicon wafers are

bonded. Part of one of the wafers is selectively removed to leave a thin

uniform layer of crystalline Silicon on top of an insulating layer of Silicon

dioxide. Patterned local oxidation of the single crystal Silicon film forms the

lateral isolation. Wafer bonding is well suited for high performance CMOS,

BiCMOS and higher power devices. Figure (4) is a diagram showing a cross section of wafer bonded

SOI.

A patented

process called Smart Cutâ is a very promising wafer bonding technique.3 Smart Cutâ starts

with an oxidized seed wafer. Hydrogen is implanted into the Silicon wafer

through the oxide. The depth of the implant is controlled by the implant

energy. The seed wafer is aligned and bonded to a handle wafer. The bonded

wafers are heated in an oven. The heating causes the wafers to split along the

Hydrogen implanted plane. The result is a thin film of crystalline Silicon from

the seed wafer resting on an insulating Silicon dioxide layer. The handle wafer

provides strength and support for the finished product. The remaining seed

wafer can be used again.

Figure (4) Diagram of Bonded Wafer Cross

Section

Smart Cutâ was

developed at CEA-LETI; an applied research laboratory operated by the French

Atomic Energy Commission. Soitec obtained an exclusive license for the initial

Smart Cutâ patents. Soitec now supplies nearly 80 percent of the

worlds SOI wafers.1 Soitec is planning

to construct a new factory capable of producing 1 million 12 inch SOI wafers

yearly. The plans call for the factory to be producing wafers by 2008.

Concluding

Remarks

All

of the aforementioned technologies have advantages and disadvantages. Table (1) compares some of their features. DI and

SOS still have their niche applications. Bulk Silicon wafers using junction

isolation will most likely dominate the semiconductor industry for many more

years. Bonded wafer SOI has entered the mainstream and will continue to

increase its market share. This should create a reliable source for bonded SOI

wafers and make SOI an attractive technology for radiation tolerant devices.

Any radiation tolerant design should consider if the technology used will be

available for the life of the system. The Strategic System Program is relying

on bonded wafer SOI technology for most of their future applications. For

questions, NSWC Crane POC is 812-854-2105.

|

|

|

SOI

|

SOS

|

DI

|

Bulk

|

|

Price

|

|

High

|

High

|

High

|

Low

|

|

|

|

|

|

|

|

|

Technologies

|

Bipolar

|

Good

|

Poor

|

Good

|

Good

|

|

|

C-MOS

|

Good

|

Good

|

Good

|

Good

|

|

|

High

Voltage

|

Fair

|

Good

|

Good

|

Good

|

|

|

Bi-CMOS

|

Good

|

Poor

|

Fair

|

Good

|

|

|

Passive

Devices

|

Fair

|

Good

|

Fair

|

Fair

|

|

|

|

|

|

|

|

|

Radiation

|

Total

Dose

|

Good

|

Fair

|

Good

|

Good

|

|

Environment

|

Prompt Dose

|

Good

|

Good

|

Good

|

Poor

|

|

|

Single

Event

|

Good

|

Good

|

Good

|

Fair

|

|

|

|

|

|

|

|

|

Performance

|

High

Speed

|

Good

|

Good

|

Fair

|

Good

|

|

|

High

Voltage

|

Fair

|

Good

|

Good

|

Good

|

|

|

Low

Power

|

Good

|

Good

|

Fair

|

Fair

|

Table (1)

Feature

Comparison

Bibliography

1 Russ Arensman, Engineering

Design News/Electronic Business, EDN.com,, 7/1/2006

2 Toshiyuki Nakamura, et al.,

Oki Technical Review, October 2004/Issue 200 Vol.71 No.4, pg. 69

3 G.K. Celler and Sorin

Cristoloveanu, Journal of Applied Physics, May 2003, Volume 93, No. 9, pg.

4962