SPRAY COOLING

COMPARATIVE ANALYSIS

21 June

2001

Prepared by:

Naval Surface

Warfare Center

Crane Division

300 Highway 361

Crane, Indiana

47522-5001

Goals

The main objective of this project is to evaluate the

effectiveness of spray cooling technology for Commercial Off The Shelf (COTS)

electronics in military applications.

Positive results from this evaluation will provide the military with a

COTS solution option to mitigate the environmental risks and allow the insertion

of state-of-the-art high-power, high-density commercial

electronics.

Background

The use of COTS

electronics in military systems has become a fact of life. Due to the shift toward use of commercially

available off-the-shelf items, the military as a customer has become less of a

driving force in the design of these products.

There has been a large reduction in the number of manufacturers willing

or able to supply “ruggedized” electronics that will meet the stringent

environmental, reliability and space/size requirements of military programs, yet

the military must still deploy the most capable systems possible in these harsh

environments.

Military system

designers use two basic techniques to deal with the problem. One is to seek out vendors who offer

ruggedized products that are designed to meet the harsh requirements and build

the system in a traditional enclosure.

This approach often works, but there are many limiting problems, such as

very few sources for critical parts, tight design tolerances, and

mechanical/material issues. Enclosures for these systems offer some

protection from the external environment, but are often limited to the level

that the ruggedized components can tolerate.

The other approach is to

design enclosure-based protection for the off-the-shelf products so that the

demanding external environment doesn’t affect the more delicate internal

electronic parts. The enclosure, in this

case, becomes more than just a box to hold the parts together and serve as a

static heat sink. This enclosure

functions as a key element of the total system solution.

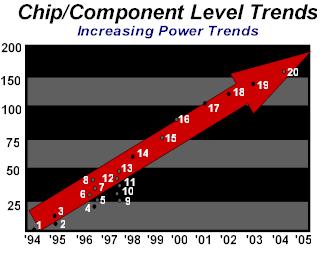

One of the major

challenges in designing such an enclosure is thermal management. As Figure 1 shows, there is a trend for

increasing power densities in emerging electronic technology. However, traditional cooling techniques

greatly limit the choice of components available to the military system

designer.

Spray cooling is a

technique where a mist of inert liquid coolant is directed upon the components

inside a sealed enclosure by pumps and nozzles.

The vapor generated after the liquid contacts the hot components can be

condensed on the chassis walls, or in a remote heat exchanger. Heat removed to the chassis walls is

externally carried through natural or forced convection. In the case of a remote heat exchanger, air

is forced over the heat exchanger core in order to reject the heat.

|

|

1

|

386 3 watts

|

|

2

|

Power PC 6 watts

|

|

3

|

486 8

watts

|

|

4

|

Pentium 13 watts

|

|

5

|

Cyrix 125 MHz 18 watts

|

|

6

|

Power PC 20 watts

|

|

7

|

Pentium Pro 25 watts

|

|

8

|

Alpha 500 MHz 45 watts

|

|

9

|

Power PC 266 MHz 25 watts

|

|

10

|

Pentium 233 MHz 27 watts

|

|

11

|

Pentium II 233 MHz 36 watts

|

|

12

|

Pentium II 300 MHz 43 watts

|

|

13

|

Ultra Sparc 50 watts

|

|

14

|

1998 CPU 50 watts

|

|

15

|

1999 CPU 75 watts

|

|

16

|

2000 CPU 85 watts

|

|

17

|

2001 CPU 125 watts

|

|

18

|

2002 CPU 140 watts

|

|

19

|

2003 CPU 175

watts

|

|

20

|

2004 CPU 200

watts

|

Figure 1-Chip/Component Level Trends.

Approach

This project focuses

on comparing the cooling effects of a standard air-cooled, COTS electronic

system to the cooling effects of a spray-cooled system manufactured by

Isothermal Systems Research (ISR) (Clarkston,

Washington).

The first phase of

this evaluation consisted of establishing a baseline with an existing VME

air-cooled card cage (see figure 2) containing four heat load

modules. The card cage is an air-cooled

enclosure capable of housing up to 21, 6U X160 VME cards, with a 700 watt power

supply containing 3 muffin fans for cooling.

The test setup contained the four heat load modules and 17 blank cards to

maintain a balanced air flow across each module (see figure 2). These load modules were VME bus slot load

boards manufactured by Dawn VME Products.

The load boards were used to simulate a working VME module and capable of

producing a fifty watt heat load per module.

Four modules were used in this test with one to four activated at various

times. The center module was always

activated and was populated with five thermocouples distributed throughout the

board as follows:

-

One on a resistor that was not powered

-

Another on a resistor with a 3.1watt heat

load

-

A third on the board surface

-

The fourth on a 3.1watt resistor that was

powered on

-

The fifth on another resistor that was not

powered

The thermocouple

locations were selected to measure temperatures of components across the

module. In addition to the thermocouples

placed on the module, others were used to measure the card cage inlet, exit and

ambient fluid temperatures. The

thermocouples were Omega T-type (Copper-constantan), with a 0.10 inch diameter

and were attached to the resistive heaters using thermal epoxy.

Figure 2-VME

Chassis & Load Board

The spray-cooling phase

consisted of utilizing a Portable Laboratory Support Unit (PLSU) and an Acrylic

Test Chassis (ATC) purchased from ISR (See Figures 3 & 4).

Figure 3-Portable Laboratory

Support Unit (PLSU)

(with front and

side panel removed)

Figure 4-Acrylic Test Chassis

(ATC)

Rear and Front

Views

For consistency, the

same set of heat load modules previously described in the air-cooled section

were utilized for the spray-cooled evaluations.

By keeping the power level on the heat load modules consistent in all of

testing, the differences in the recorded temperatures were an actual result of

the cooling methodology.

Test Procedure

The thermal

testing was divided into four major parts:

1)

Air cooling at ambient room temperature

2)

Air cooling at elevated temperature

3)

Spray cooling at ambient room temperature

4)

Spray cooling at elevated temperature

1) Air Cooling

at Ambient Room Temperature

This examination was performed at 25°C at four

different power levels 50W, 100W, 150W, and 200W. The power levels were obtained by use of heat

load modules see figure 2. Each module

was setup for 50W. Four modules were

placed in the VME air-cooled card cage.

The test data was recorded on a Fluke data logger (see Appendix B for typical data recorded).

2) Air

Cooling at an Elevated Temperature

This examination was

performed at three different temperatures 35°C, 45 °C, and,

55°C as well as four different power levels

50W, 100W, 150W, and 200W. The test

setup was similar to the air cooling at ambient room temperature test but the

test unit was placed in the thermal chamber.

3) Spray Cool at Ambient Room

Temperature

This examination was

preformed using the spray cooling system (see figure 3 and 4) in the

laboratory. The procedure is the same as

the air cooling at ambient room temperature of 25°C but ran

at four fluid flow rates, 890ml/min (15 psia), 1000ml/min (20 psia), 1300ml/min

(25 psia), and 1500ml/min (30 psia) (see Appendix B for typical data). The data

collection and evaluation remained constant throughout the evaluations.

4) Spray Cool

at Elevated Temperature

This

examination was performed at three different temperatures 35°C, 45 °C, and,

55°C, four different power levels 50W, 100W,

150W, and 200W and four different flow rates 890ml/min (15 psia), 1000ml/min (20

psia), 1300ml/min (25 psia), and 1500ml/min (30 psia). The test setup was similar to the spray

cooling at ambient temperature but the test unit was placed in the thermal

chamber.

Results/Accomplishments

The results

of this thermal evaluation indicate that a significant heat removal gain is

achieved by employing spray cooling heat transfer technology. As a result of all the testing, the spray

cooling consistently out preformed the air-cooling. The amount of improvement ranged from 5 to 20

times the heat removal of a standard air-cooled chassis depending upon the

surrounding temperature, heat load and liquid flow rate/pressure. See TABLES 1 and 2 for test data from thermocouple #3 and FIGURES 6 and 7 for graphical representations of the test

results.

FIGURE 6-AIR/SPRAY AT ROOM AMBIENT

|

Air

Cooling

Air flow : 200

ft/min

All temps for TC3 (See Fig 2)

|

|

Heat load

|

Air - 24.1C

amb

|

Air - 37.8C

amb

|

Air - 46.4C

amb

|

Air - 57.7C

amb

|

|

Watts

|

Temp. Deg.

C

|

Temp. Deg.

C

|

Temp. Deg.

C

|

Temp. Deg.

C

|

|

50

|

112.3

|

123.3

|

131.0

|

142.3

|

|

100

|

134.2

|

124.0

|

138.8

|

150.0

|

|

150

|

142.4

|

132.6

|

140.9

|

152.4

|

|

200

|

142.0

|

133.1

|

141.7

|

152.8

|

TABLE 1 AIR FLOW TEST DATA

Tc3

|

Spray

cooling

|

|

|

|

|

|

|

15 psia (890

ml/min)

|

20 psia (1000

ml/min)

|

25 psia (1300

ml/min)

|

30+ psia (1300+

ml/min)

|

Boiling

point

|

|

Heat load

|

Spray - 24C

|

Spray - 24C

|

Spray - 24C

|

Spray - 24C

|

(approx)

|

|

W

|

|

|

|

|

C

|

|

50

|

40.0

|

39.2

|

38.7

|

38.3

|

|

|

100

|

41.9

|

41.9

|

41.4

|

41.3

|

|

|

150

|

45.7

|

44.5

|

43.8

|

41.4

|

|

|

200

|

49.1

|

47.7

|

46.8

|

46.1

|

57

|

|

|

|

|

|

|

|

|

|

15 psia (890

ml/min)

|

20 psia (1000

ml/min)

|

25 psia (1300

ml/min)

|

30+ psia (1300+

ml/min)

|

|

|

Heat load

|

Spray - 35C

|

Spray - 35C

|

Spray - 35C

|

Spray - 35C

|

|

|

W

|

|

|

|

|

|

|

50

|

52.4

|

51.5

|

51.6

|

51.2

|

66

|

|

100

|

52.4

|

52.5

|

50.7

|

49.8

|

65

|

|

150

|

53.3

|

52.9

|

51.4

|

50.4

|

60

|

|

200

|

56.1

|

56.3

|

53.9

|

52.1

|

65

|

|

|

|

|

|

|

|

|

|

15 psia (890

ml/min)

|

20 psia (1000

ml/min)

|

25 psia (1300

ml/min)

|

30+ psia (1300+

ml/min)

|

|

|

Heat load

|

Spray - 45C

|

Spray - 45C

|

Spray - 45C

|

Spray - 45C

|

|

|

W

|

|

|

|

|

|

|

50

|

57

|

57

|

53

|

55

|

66

|

|

100

|

58

|

57

|

54

|

55

|

65

|

|

150

|

60

|

58

|

55

|

57

|

66

|

|

200

|

61

|

58

|

57

|

56

|

65

|

|

|

|

|

|

|

|

|

|

15 psia (890

ml/min)

|

20 psia (1000

ml/min)

|

25 psia (1300

ml/min)

|

30+ psia (1300+

ml/min)

|

|

|

Heat load

|

Spray - 55C

|

Spray - 55C

|

Spray - 55C

|

Spray - 55C

|

|

|

W

|

|

|

|

|

|

|

50

|

59.6

|

57.0

|

54.5

|

54.4

|

66

|

|

100

|

60.5

|

59.8

|

57.5

|

57.9

|

65

|

|

150

|

63.0

|

59.9

|

57.7

|

59.6

|

65

|

|

200

|

63.9

|

62.6

|

60.7

|

55.2

|

65

|

TABLE 2 SPRAY COOLING TEST DATA Tc3

FIGURE

7-AIR/SPRAY AT 55 DEGREES C

The results of this investigation clearly indicate that the spray cooling

system was not challenged at the stated temperatures, heat loads and flow

rates/pressures. In order to more

thoroughly evaluate spray cooling, NSWC Crane has identified a military system

slated to utilize spray cooling in a harsh environment and are in the process of

performing a reliability projection of the COTS electronics. This analysis will yield a reliability

comparison (air vs. spray) at the system, sub-system, module and component

level.

The next

phase of evaluations will include:

§

Reliability

Verification

§

Environmental

Certification

o

Shock/Vibration

o

Toxicity/Flammability

o

Mechanical

o

Altitude

o

Humidity

§

Material Compatibility

Analysis

§

High Power

Component/Module Testing

APPENDIX A

3M Fluorinert PF

5060