Download the PDF file

Prepared for:

The Naval Surface

Warfare Center, Crane IN

29 September 2000

Prepared by:

Systems Design and

Analysis, Inc.

1398 North Shadeland Ave. suite 2235

Indianapolis, IN

46219-3619

www.sdaindy.com

This report is authorized under NSWC, Crane contract

N000164-98-D-0025, Delivery Order D0013, Paragraph 3.2(Task B).

This market investigation is primarily directed at

the identification of commercially available Spray cooling technologies which

could be used or adapted for use in cooling and/or heating Commercial Off the

Shelf (COTS) Electronic assemblies. Additionally, this investigation provides a

comparison of the various alternative cooling technologies and assesses their

applicability to the use of COTS in a military environment. The scope of this

investigation was general in nature due to cost and schedule limitations.

Task 1 Conduct a market

investigation of existing spray cooling technologies.

The market survey was conducted using the following

three approaches:

1. Discussions with experts in the field regarding

the use of dielectric liquids to cool electronics

2. A literature and file search for related

information

3. A detailed WEB search for information related to

spray cooling of electronics using dielectric liquids

Expert Knowledge

Discussions with experts in cooling research in the

academic community and experienced designers of cooling systems revealed that

significant basic research has been done in the area of dielectric liquid

cooling. Transfer of the research technology to commercial products has been

very limited. A recent SBIR (1996) effort involved comparison of dielectric

liquid cooling techniques. That effort included high heat flux liquid flow

through cooling, Spray Cooling and Jet Impingement cooling techniques applied to

practical military thermal management examples. SDA attempted to obtain copies

of the SBIR Phase II (N92-136) report detailing results. Re-organization of SBIR

offices and personnel has made it difficult to obtain the report. However, SDA

subcontracted with a long time associate that was the cognizant Navy technical

expert for that SBIR. His intimate knowledge of the SBIR efforts and 25 years

plus experience in the electronics cooling area was tapped for this market

survey. SDA also previously investigated dielectric liquid cooling research at

Purdue University, with specific interest in developing practical applications.

A foremost expert in the field at Purdue has been conducting research for over

15 years and has provided practical solutions to many commercial and government

customers such as CRAY Research, AT&T, IBM, and the US Air Force. It is

interesting to note that Purdue has been consulted numerous times regarding

Spray Cooling technology included as part of a larger system or product. SDA

refreshed the association with Purdue to obtain current research information.

Literature/ File Search

A literature/file search revealed some magazine

references to spray cooling and to Isothermal Research Systems (ISR) technology

development. It was also found that ISR previously received Phase I and II SBIR

funding for Change of Phase (COP) Spray cooling technology development. More

importantly, it was found that ISR was recently awarded a $35,000,000 contract

by the Naval Air Warfare Center Aircraft Division for the development of

airborne Spray Cooling systems.

Proceedings from the June 2000 DARPA sponsored

HERETIC Program Principal Investigators’ meeting were reviewed. The vision of

the HERETIC Program is “to develop micro-scale solid state and fluidic heat

removal devices that are integrable with dense electronics and optoelectronics

in order to short circuit the thermal resistance between the heat sources in the

electronics or optoelectronics devices and the thermal sinks.” Review of the

HERETIC material indicated a great deal of basic research is being conducted in

this area at Institutions such as MIT, Harvard, Stanford, and Carnegie Mellon

just to name a few. Other organizations such as the Jet Propulsion Laboratory

and Rockwell Science Center, LLC are participating. Virtually all of this work

involves basic research aimed at integrating cooling technologies with

semiconductor structures or subassemblies of semiconductors. Much of it is very

esoteric in nature. For example, one of the papers reviewed is titled Heat

Removal by Inverse Nottingham Effect with Heat Pipes. Practical applications

resulting from HERETIC Program research are years away.

WEB Search

To complete the market survey, a WEB search for

information on Spray Cooling technologies was conducted using a variety of

search words and terms to improve the chances of finding as much related

information as possible. The initial results of the search appeared to indicate

that a considerable amount of research on spray cooling has been reported by

academic sources such as Purdue University, the University of Kentucky, The

University of Minnesota, and the University of Maryland. Information indicated

that this research is basic in nature and that little or no commercial product

development work is in progress. Upon closer investigation, it was discovered

that no current web information could be found for University of Maryland

efforts. The University of Minnesota research web site dealt with Spray Cooling

techniques, but was very incomplete. A University of Kentucky web site did not

refer to current work that might be applicable, although it is believed that

Spray Cooling research was performed in recent years. ISR is known to have

worked with the University of Kentucky in the past. The Purdue University web

site was very complete and current, detailing extensive liquid cooling research

efforts and published papers.

Only one corporate WEB site was found with

significant spray cooling information, that of ISR. The ISR WEB site contained

extensive information on COP Spray Cooling, the ISR design approach, and the

firm’s experience with cooling COTS in a military environment. ISR equipment has

been under evaluation in the Marine Corp Advanced Amphibious Assault Vehicle

(AAAV) for some time. Discussions with company personnel have confirmed that, at

present, ISR is the only company known to be offering COP spray cooling

enclosures for use with COTS in a military environment.

Market Investigation Conclusions

The market investigation led to the following

conclusions:

1. The ISR technology is the only one known to be

directed at the cooling of low to medium power COTS electronics in a military

environment.

2. The ISR technology is the only one known to have

been evaluated by the military.

3. The recent large contract award to ISR by the U.S.

Navy indicates that ISR is the leader in commercially available spray cooling

technology and may be the only near term supplier of this technology.

Task 2 Provide a comparison of

spray cooling to other cooling technologies.

In conducting a comparison

of the various other cooling techniques to Spray Cooling it was decided that SDA

should identify potential COTS liquid cooling techniques and traditional methods

listing the advantages and disadvantages of each. That data is summarized and included as

Attachment 1.

A review of the

advantages and disadvantages of the cooling techniques in Attachment 1 leads to the immediate conclusion that almost any of

them could be the approach of choice in a particular situation. An example might be the direct immersion,

forced convection method to cool very high power density COTS electronics even

though this selection might be somewhat unique. It could very well be the only

feasible technical approach for a particular situation. In many cases, typical forced air cooling

will still be the method of choice.

Based on the recognition that military applications are varied, selection

of a particular technique as a single standard solution is not advisable. It

would be highly desirable have available a complete arsenal of possible

solutions and not focus on a “one size fits all” approach.

The SBIR efforts

previously mentioned can be summarized by saying that each technique examined is

appropriate in specific real world situations.

Purdue University compared three dielectric liquid cooling techniques;

Flow Through, Spray, and Jet Impingement. The Flow Through cooling technique

demonstrated heat removal capability of over 3000 Watts from a Standard

Electronic Module (SEM) Format E configuration (approx. 6” x 6”). The spray cooling technique demonstrated the

capability to cool a circuit card of SEM E size dissipating over 1000 Watts. The

Jet Impingement technique demonstrated cooling capability of over 5000 Watts on

a SEM E clamshell style circuit card.

Of particular interest to this investigation are the Spray

Cooling and Jet Impingement performance

results demonstrated by Purdue. Spray

Cooling offers good performance in applications with low to moderate heat

removal requirements. The individual

Spray Cooling components, such as nozzles, plumbing, pumps, filters, and heat

exchangers are commercially producible. However, it should be noted that special

machining capabilities are required to manufacture spray nozzles to the

precision and tolerance required. Purdue

research revealed variation in nozzle performance due to contamination,

corrosion, and long-term wear.

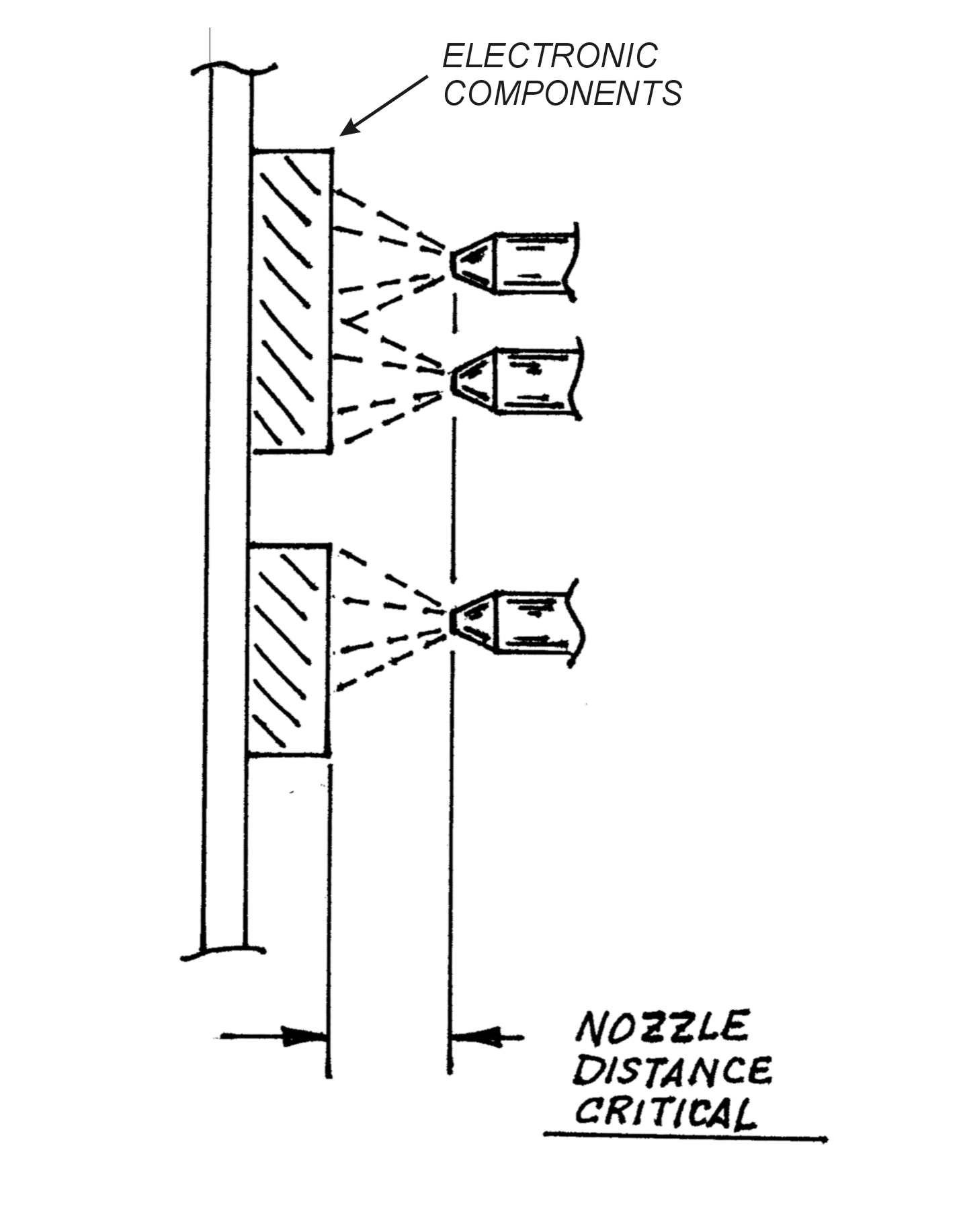

Placement of spray nozzles is fairly critical to assure adequate

cooling. A simplified drawing of the

Spray Cooling concept is shown in Figure 1.

Figure 1. Spray Cooling Configuration

Example

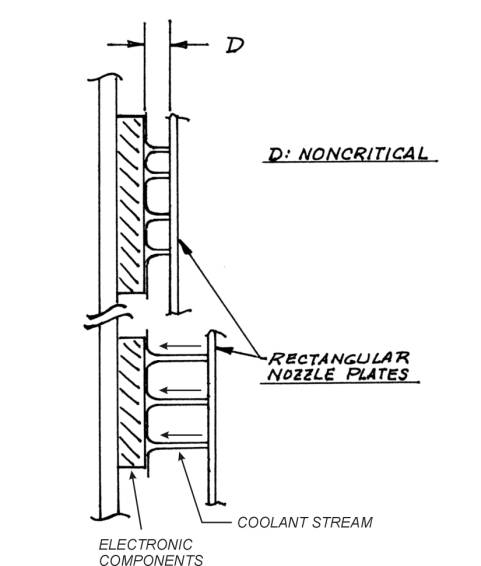

Jet Impingement offers excellent cooling performance

in low to moderately high heat applications. Production of components is quite

easy because precision manufacturing is not required. A simple Jet Impingement

system could be constructed that delivers and directs dielectric liquid through

holes (nozzles) in a plate. Rectangular or circular shapes can be used and

tailored for size, flow rate, and velocity to match the heat dissipating

components. Precise positioning is not required. Purdue research found that

contamination, corrosion, and wear of Jet Impingement nozzles are of very little

concern, even though the dielectric fluid should be filtered and conditioned in

both Spray and Jet Impingement configurations. While no commercial product

currently exists using the Jet Impingement technique, it should be relatively

simple and low risk to develop and demonstrate a viable Jet Impingement cooling

system. A simplified drawing of the Jet Impingement concept is shown in

Figure 2.

Figure 2. Jet Impingement Cooling

Configuration

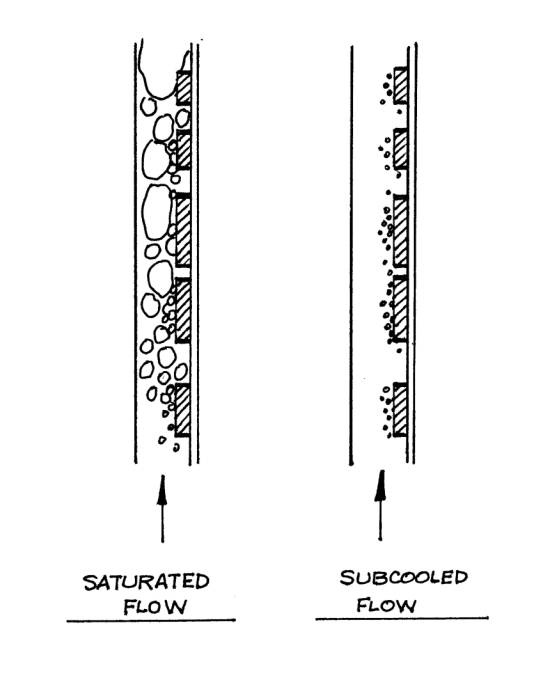

Figure 3. Direct Immersion and Flow

Through/Channel Flow Cooling

Two other interesting dielectric liquid cooling

concepts are presented here for information. Direct Immersion and Flow

Through/Channel Flow liquid cooling are alternatives to Spray or Jet Impingement

methods. An electronic package, such as a power supply, can be filled (Direct

Immersion) with a dielectric fluid that transfers heat from electronic

components to an external heat sink through conduction/convection. A larger

volume of fluid may be required depending on the size of the flow channel(s);

but nozzles, plumbing, a pump, and filter required by Spray or Jet impingement

methods are eliminated. A variation of Direct Immersion is a Flow

Through/Channel Flow configuration that directs coolant over the entire surface

of an electronic circuit card and components. Nozzles are not needed, plumbing

is minimized or eliminated, a pump circulates the coolant and a filter traps

contamination. Figure 3

shows bubbles generated by the COP action as heat is transferred from components

to the coolant. In the saturated flow example, large bubbles are generated.

Large bubbles may inhibit liquid contact with electronic parts; therefore

reducing heat transfer. This condition should be avoided. The subcooled flow

example illustrates the preferred situation where very small bubbles

(micro-bubbles) are produced by the COP actions that naturally condense back

into the bulk coolant flow. Subcooling is achieved exactly as the term implies.

The dielectric fluid is cooled some amount below the COP point based on the

specific system requirements. An important fact to note is that a variety of

dielectric fluids exist that can be mixed to achieve specific cooling

performance.

Cooling COTS systems in military environments is a

challenge that must be addressed by all military branches. COTS technology

brings the benefits of high performance at a low initial cost. However,

long-term cost of ownership may be high depending on reliability and

supportability. Developing appropriate cooling techniques will be a major factor

in the long-term viability of COTS technology in military applications.

This investigation confirmed that the only company

known to be doing commercial development work on Spray Cooling for COTS in

military applications and certainly the only company shipping operational Spray

Cooling systems is ISR. The fact that a market investigation was commissioned

indicates interest in liquid cooling technology exists within the Navy. SDA

experience confirms that cooling COTS equipment is recognized as a significant

part of successful development efforts. In the last 3 years SDA provided

engineering support to a Navy project to develop a commercial replacement for a

custom designed military system. Keeping the COTS electronics cool was a major

part of that effort. SDA has also discussed liquid cooling of COTS in extreme

environments with a military contractor. Other corporate or government

development work on Spray Cooling systems or liquid cooling was not discovered;

however, such work could be underway at firms under government contract with

highly restricted public access.

There is a risk in having only one supplier of liquid

cooling technology. Interruption of product supply, for any reason, can cause

large problems for military customers. One supplier that produces only Spray

Cooling equipment might not be able to handle peak demand periods or survive low

demand periods. Certainly, proprietary technology should be avoided. While

reliance on one technology or one supplier should be avoided, allowing a unique

solution for each system must be avoided. A balance between a mandated single

dielectric liquid cooling approach and many unique approaches should the goal of

the Navy.

Recommendations

1. Proceed with the evaluation of spray COP for use

as a general solution for cooling COTS. Spray COP is the most available advanced

cooling technique at this time and is applicable to situations where the use of

COTS is a necessity. It is the only technique with hardware available at this

time.

2. Do a feasibility study on the development and

demonstration of Jet Impingement COP cooling techniques to increase available

cooling options, cooling capacity, and augment Spray COP capabilities. Jet

impingement COP offers the potential for higher cooling capability and lower

manufacturing cost. It is also not a proprietary technology at this time.

3. Do a feasibility study on the development and

demonstration of Direct Immersion and Channel Flow COP cooling techniques to

offer solutions not provided by Spray Cooling or Jet Impingement. It is also not

a proprietary technology at this time.

4. Establish a second source for any liquid cooling

technology used or purchase all design rights and manufacturing documentation.

5. Monitor liquid cooling technology developments on

a regular basis.

|

|

Complexity

|

Availability

|

Effectiveness

|

Cost

|

|

Liquid Flow Through

|

|

|

|

|

|

|

|

|

|

|

|

Spray Cooling

|

|

|

|

|

|

Jet Impingement

|

|

|

|

|

|

Direct Immersion

|

|

|

|

|

|

Channel Flow

|

|

|

|

|

<align="center">COMPARISON OF

COOLING TECHNIQUES

APPLIED

TO COMMERCIAL PRODUCTS USED IN

MILITARY ENVIRONMENTS</align="center">

Introduction

Thermal Control, more

commonly know as cooling, is a critical engineering discipline that must be

successfully applied to ensure required performance and reliability in military

electronic systems constructed using commercial-off-the-shelf (COTS)

products. Studies performed during the

last 40 years investigating military electronic system failures indicate that

the majority were thermally related.

Electronic parts fail catastrophically from simple overheating or due to

a breakdown of components and attachment mechanisms brought on by thermal

cycling that causes excessive expansion/contraction of internal parts and

mounting substrates.

The prevention of catastrophic thermal

failure must be the primary goal of all electronic thermal management

schemes. Catastrophic failure can be

defined as the immediate, thermally induced total loss of electronic function in

a particular component or system. To

avoid electronic equipment failure, it is therefore essential to minimize the

thermally induced failure rates of each component comprising an electronic

system. The two main problems that must

be avoided are electronic components operating at elevated temperatures and

excessive thermal cycling. Each can act

independently to induce failure. In

concert they can act synergistically to assure premature failures in electronic

systems.

Mechanical/thermal engineers have spent untold hours

developing highly sophisticated electronic packaging to protect against the

effects of heat, cold, vibration, shock, electromagnetic radiation,

electromagnetic noise, and, corrosion to ensure survivability in severe military

environments. The requirement to use

COTS in military electronic systems offers many technological and performance

advantages but, in turn, causes incredible heartburn in packaging them in

ruggedized schemes so as to survive the same harsh environments as "classic"

military hardware did. While providing

relatively low cost and high electronic performance, COTS hardware is basically

fragile in environments other than relatively benign laboratory or industrial

environments. Providing proper

ruggedized protective packaging without turning enclosure systems into

overweight, complicated, and expensive boxes is a challenging task.

Potential Thermal Control Techniques for use

with COTS

Listed in ascending order of performance.

-

Natural air

convection

-

Forced air

convection

-

Module thermal

plane conduction to air or liquid convection heat exchangers

-

Radiation

-

Heat pipe

technology (very difficult to attach to COTS modules, either as tubes or as

"flat, shape-conforming plates")

-

Dielectric

liquids, e.g., non-CFC perfluorohexanes (3M Fluorocarbons), PAO (Coolanols),

Silicone oils.

Note: "Fluorocarbons" are the

much preferred dielectric liquids due to their safe performance

properties.

-

Direct

immersion natural convection [sensible and Change of Phase (COP)

mechanisms]

-

Direct

immersion forced convection (sensible and COP)

-

Spray

("atomized mist") COP

-

Jet impingement

COP

Note: Sensible in this context is a thermal

term defined as a non COP technique. It

is not intended to convey a good or bad comparison.

NATURAL AIR CONVECTION:

ADVANTAGES

-

Abundant, free supply

-

Requires no man-made pumping

mechanisms.

-

Minimal maintenance

-

No weight and volume impacts on

platform

-

Can be an open system, i.e.,

once used it can be dumped

-

Systems are

inexpensive

NATURAL AIR CONVECTION: DISADVANTAGES

-

Very low heat removal

capacity

-

Must have a gravity field

present for buoyancy action

-

May require

cleaning [foreign object debris, e.g., dirt, chemicals, fuel, etc, foreign

object debris (FOD)] and dehumidification

-

Performance is

adversely impacted by altitude. High altitudes severely reduce air molecular

density and heat capacity of the coolant air.

-

Equipment must be configured to

enhance natural flow "updraft."

-

Components must

be arranged to keep the flow from absorbing excessive heat from "lower"

components before reaching others that require substantial cooling.

-

All components

may not be reached by the air flow.

FORCED AIR CONVECTION:

ADVANTAGES

-

Abundant, free

supply if taken from atmosphere

-

Much more

efficient in heat removal than natural air convection.

-

May be taken

from turbine engine bleed air or other source and conditioned to a low

temperature.

-

Can be used in

open or closed systems.

-

No atmospheric

altitude impact if bleed air supplied

FORCED AIR CONVECTION: DISADVANTAGES

-

Engine bleed

air or other supply requires conditioning (throttling to lower temperature,

filtering, etc.).

-

Engine bleed

air or other supply may be limited, depending on how supply is prioritized to

other systems.

-

Requires more

complex pumping, ducting, and gasketing hardware. This adversely impacts platform weight,

volume, and structural fatigue life of platform.

-

Must be maintained

-

Atmospheric or "cabin" air may

require filtering to eliminate FOD.

-

Added weight

may require extra electronic system dynamics isolation if not hard

mounted.

-

Convection

surfaces must be free from debris and corrosion, to maintain convection

coefficients.

CONDUCTION: ADVANTAGES

-

May utilize

installation structures to reach an ultimate "heat sink" such as the ambient

environment or a large system/platform heat exchanger.

-

Module cards

may use attached thermal planes of aluminum, copper, Invar (heavy), or polymer-

or metal-matrix composite materials to transfer heat from components to other

locations such as conduction/convection heat exchangers.

-

Thermal planes

may be double-walled to pass a coolant.

-

Basic

conduction mechanisms require no extra pumps, ducting, filters, collection

reservoirs, etc.

-

May be

inexpensive unless more expensive materials are used. This in turn depends on cost of ownership and

reliability.

CONDUCTION: DISADVANTAGES

-

Requires high

pressure, intimate contact between heat transfer surfaces. This may require extra machining and surface

preparation, "thermal grease," other non-grease fillers.

-

Material thermal conductivity

dependant

-

Thermal paths

through multiple parts and surfaces will impose thermal resistances.

-

Transfer surfaces must be

maintained free of corrosion.

-

Transfer

surfaces must be free from vibration induced failures (separations leading to

more thermal resistance.

HEAT PIPE TECHNOLOGY

-

Heat pipes can

provide great thermal transfer through their liquid to vapor COP action; much

greater than conduction and air convection mechanisms. However, with respect to COTS electronics,

unless the modules are designed specifically to incorporate tubular or flat,

conforming hardware, they are not fiscally suitable.

RADIATION

-

Radiation is

not a good choice here either, as in a lot of "racked and stacked" electronic

systems. The very fact of close

proximity to other, equally dissipating (and receiving) units, will cause

minimal, if any, "net losses" of thermal energy.

DIELECTRIC LIQUIDS: ADVANTAGES, IN GENERAL

-

Can be used in

direct contact with electronic components, eliminating thermal path

resistances.

-

Can deliver

high heat transfer removal rates compared to air systems and conduction schemes

with high path resistances.

-

The

perfluorohexanes, i.e., "fluorocarbons" such as 3M Company Fluorinerts, are very

environmentally and "human" safe due to their inert, nontoxic, nonresidue, and

nonflammable nature.

-

Saturation

temperatures can be somewhat tailored to match component environment

requirements. this eliminates elevated

temperatures.

-

When used as

COP, component temperatures can be maintained reasonably constant. This eliminates thermal cycling.

-

Large

quantities are not necessarily required, thus avoiding excessive weight

(specific gravity for FC-72 =

1.62).

The following

considerations must be balanced when using an existing liquid or tailoring

one.

-

Cost/availability

-

Thermal

transfer properties

-

Specific

heat

-

Thermal

conductivity

-

Saturation

temperature and pressure (i.e., @ "boiling" COP

)

-

Freezing

temperature (pour point)

-

Viscosity

-

Density

-

Circulation

rates

-

Dielectric

strength

-

Inertness and

compatibility

-

Toxicity

-

Thermal

decomposition and impurities

-

Surface

tension

-

Moisture

effects

-

Pour and flash

points

-

Flammability

-

Oxygen displacement

DIELECTRIC LIQUIDS: DISADVANTAGES, IN

GENERAL

-

Not as good as

water for heat removal. At 70 - 80 F the specific heat of water at 70 - 80 F =

0.99Btu/LB while the specific heat of the fluorocarbons = approximately

0.25. However, water cannot be readily

used as a dielectric direct contact fluid.

-

Requires

complex hardware (especially for sprays with very critical nozzle dimensioning

and manufacture)

-

Cost can be

high, although continued use has caused reductions in cost.

-

Are heavier

than water. At specific gravity = 1.62

for FC-72, one gallon = approximately 13.2 pounds (assuming 8.2 lbs/gallon for

water). However note that huge

quantities are not necessarily required.

-

COP action

requires fluid reconditioning, i.e., temperature control, condensation,

etc.

DIRECT IMMERSION:

NATURAL CONVECTION, ADVANTAGES

-

Natural convection

requires no fluid moving hardware.

-

Direct contact

with parts

-

Can be used in either

sensible or COP methods.

-

See above

general advantages.

-

Can provide

close temperature control when used as COP.

-

See dielectric

liquid advantages.

DIRECT IMMERSION: NATURAL CONVECTION, DISADVANTAGES

-

Lowest heat

removal capability of the fluorocarbon mechanisms

-

Can be heavy,

depending on system volume.

-

See dielectric

liquid disadvantages.

DIRECT IMMERSION: FORCED CONVECTION, ADVANTAGES

-

Greater thermal

transfer than previous.

-

Direct contact

with parts.

-

With COP and Channel Flow COP, heat removal begins to exceed

other methods discussed previously and results in approximate constant part

temperatures. See above advantages.

-

When used as COP and

Channel Flow COP, subcooled inlet liquid can cause complete condensation of the

vapor micro bubbles within the bulk fluid flow, thus requiring conditioning only

a single phase liquid. This leads to a

more efficient mode of heat exchanger action and system operation.

-

More simple method

than spray and jet methods, yet affording high heat flux values.

-

See dielectric

liquid advantages.

DIRECT IMMERSION: FORCED CONVECTION,

DISADVANTAGES

-

Requires pumping

hardware and associated maintenance/cost.

-

Requires fluid

reconditioning.

-

Critical heat flux of the liquid coolant must be matched to the

system requirements to avoid exceeding nucleate boiling regime and leading to

overheating and catastrophic failure.

This is not necessarily a "disadvantage," just a design requirement.

-

See dielectric

liquid disadvantages.

SPRAY COP: ADVANTAGES

Previous

studies have indicated these advantages.

-

Can provide high heat

flux.

-

Gives good coverage

due to atomizing action.

-

May use less fluid

than forced convection, bulk flow mechanism.

-

May use

slightly less fluid than jet impingement.

SPRAY COP: DISADVANTAGES

Previous

studies have indicated these concerns.

-

Requires special

spray nozzles.

-

Requires complex fluid handling and reconditioning (condensation,

heat exchanger with ultimate "sink", etc) equipment. This adds weight and associated penalties to

platform systems.

-

Quality control is critical.

Studies have shown that the nozzles are very sensitive to manufacturing

tolerances and quality.

-

Nozzle action can

change in time due to erosion, corrosion build up, and contaminants.

-

Spray distance

to components is critical for development of "spray cone."

-

Spray velocity and momentum can be critical. If too great, it can lead to part erosion,

and splashing away without proper wetting of the part surfaces, leading to poor

cooling.

-

Proper distance and some degree of confinement has been found

necessary to avoid separation from surfaces, leading to poor wettability.

-

Must be used only as

COP. Has poor sensible cooling action

-

High pressure

required.

JET IMPINGEMENT COP: ADVANTAGES

Previous

studies have indicated these advantages.

-

Very high heat

fluxes can be achieved if desired.

-

Critically designed/manufactured nozzles not required. Plates with machined openings can be used.

-

Flow can be localized

if only a single jet is used.

-

Multiple jets placement is not as critical with respect to closeness

to/from parts.

-

Jet hardware is more repeatable and durable due to less precision

required in jet openings.

-

Will not splash and separate away from parts. There is no cone effect requiring specific

locations with respect to parts.

-

Thermal transfer can also take place in sensible regime better than

with spray. This could benefit overall

cooling and offer some redundancy.

JET IMPINGEMENT COP: DISADVANTAGES

Previous

studies have indicated these concerns.

Cooling Technique

|

Cooling

Capacity

|

Complexity

|

Weight

|

Cost

|

Description/Comment

|

Overall

Rating

1=poor 10=excellent

|

|

Radiation

|

Low

|

Low

|

Low

|

Low

|

Does not allow

dense COTS card packaging. Very low cooling capacity.

|

1

|

|

Natural Air

Convection

(1)

|

Low

|

Low

|

Low

|

Low

|

Low cooling

capacity. Subjects COTS cards to heat, cold, humidity, salt, and contamination

of military environment.

|

1

|

|

Forced Air

Convection

(1)

|

Low

|

Low

|

Low

|

Low

|

Low to moderate cooling

capacity. Can be used in open or closed systems. Subjects COTS cards to heat,

cold, humidity, salt, and contamination of military environment.

|

3

|

|

Module Thermal

Plane Conduction to Heat Exchanger

|

Moderate

|

Moderate

|

Moderate

|

Moderate to

High

|

Requires custom

machined conduction planes for each COTS card. Moderate heat removal capacity.

Can be used in closed system.

|

3

|

|

Heat Pipe

Technology

|

Moderate

|

High

|

Moderate

|

Moderate to

High

|

Expensive and

very difficult to adapt to COTS cards.

Normally designed into card frame and enclosure structure.

|

1

|

|

Direct

Immersion

Natural Convection

|

Low to

Moderate

|

Low

|

Depends on type

and quantity of coolant fluid

|

Depends on type

and quantity of coolant fluid

|

Good heat

removal capacity. Technically simple. Cost and weight of coolant may be

problematic in some applications. Requires sealed enclosure. ILS issues may

exist.

|

6

|

|

Direct

Immersion

Forced Convection

|

Moderate to

High

|

Low to

Moderate

|

Depends on type

and quantity of coolant fluid

|

Depends on type

and quantity of coolant fluid

|

Very good heat

removal capacity. Cost and weight of coolant and fluid handling/reconditioning

equipment may be problematic in some applications. Requires sealed enclosure.

ILS issues may exist.

|

7

|

|

Spray

Change

of Phase (COP)

|

Moderate to

High

|

Moderate to

High

|

Depends on type

and quantity of coolant fluid

|

Moderate to

High

|

Very good heat removal capacity.

System contains special spray nozzles, fluid handling /reconditioning equipment,

and electronic controls. Requires sealed enclosure. Long term reliability

unknown. ILS issues may exist.

Most developed cooling

technique for COTS at present.

|

8

|

|

Jet

Impingement

Change of Phase (COP)

|

Moderate to

High

|

Moderate to

High

|

Depends on

type and quantity of coolant fluid

|

Low to

Moderate

|

Excellent heat removal capacity. System contains simple

spray nozzles, fluid handling/reconditioning equipment, and electronic controls.

Requires sealed enclosure. Potentially lower cost than Spray. High

reliability. ILS issues may exist.

Potentially the best system when fully developed.

|

8-10

|