Recently, NSWC Crane was approached

to help perform failure analysis, fault determination and isolation on laser

damaged interline transfer Charge Coupled Devices (CCDs). The initial task

objective was to understand device construction/operation and determine which

laser-induced defects generate various failure modes viewed on the video output

of the CCD. Better understanding of CCD chip structure and operation, as well

as its failure modes, should facilitate better laser hardening

techniques.

After considerable effort was spent

acquiring data and information on device structure and operation, fault sites

that caused various failure modes on the CCD output were analyzed. The failure

modes included, but were not limited to the following:

Black

Spots

White Spots

Colored spots

Horizontal Black Lines

Vertical

White Lines

Blooming Cross-Like White Spot

Waterfall Effect

Half Blank

Screen

Blank Screen

Upon completion of both construction

and fault site analysis on numerous CCDs, theories were developed for various

chip behaviors observed after damage by a laser beam. Simulations were then

developed and tested to verify findings.

The intent of this document is to provide the reader with an

understanding of the work accomplished in support of this effort and provide the

insight necessary to introduce new and better laser hardening techniques.

Chip-level Basics of Failure

Analysis

This section will discuss the

process steps and techniques that are utilized while performing failure analysis

on Charge Coupled Devices (CCDs). The processes and techniques are discussed

below in typical order that they are undertaken during failure analysis. The

intent of this section is to provide information to the reader that will allow a

better understanding of the problem solving

process.

Review of Background Data

Associated with Anomalous CCDs

The

history and data of what has been done to a given CCD is thoroughly reviewed and

addressed. This includes the number and location of laser shots, energy and

frequency range, video image output of the device after each shot, as well as

other conditions related to the shots or response of the component.

All related

data, whether jpgs, gifs, Excel files, observations, etc, are reviewed together

with the electrical specifications related to a given CCD, so that the exact

state and behavior of the device is known and can be confirmed before failure

analysis begins. If the unit were fully functional, then a review of the

specifications would usually be adequate before proceeding with construction

analysis, simulation of failures and

deprocessing.

Capture Video Output of Operating CCD

During this step of the failure

analysis process, the unit is connected to power and its output is monitored via

a video recorder in order to observe the unit’s response to given laser damage.

When possible, this is done with the lens in place,

to help orient the video of the damaged area to the physical location of

the damage on the die surface. Light intensity is varied from zero light to bright light to record changes in video output at the location of

damage. Depending on the output and the behavior of

the CCD, the same operation is accomplished with or without the filter, and with

the use of fine focused microscope light or low power laser. This has

also proved to be beneficial in determining the exact failure modes of the

individual laser shots.

Package

opening

Generally, the cover glass needs to

be removed to complete the die inspection and photo documentation process and

also to de-process and identify depth and severity of the laser damaged areas.

Removal of the cover glass is accomplished by milling around the attached area

of the cover glass until breaching the package cavity. The cover glass is then

removed with a small probe or tweezers. The exposed device is cleaned with

alcohol, air and ultrasonic if needed. During this process, it is important to avoid disturbing

bond wires or permitting glass or package chips to damage the organic covered

array area. If removal of the cover glass is for the purpose of filling the cavity with fluid

and resealing, milling is continued until residual glass is removed and the

attachment area is smooth and level. The package is once again cleaned with

alcohol and air. The distance between the sidewalls of the package are measured

and a diamond saw is used to cut a new cover glass to replace the removed cover glass. Another opening method that has had

marginal success, is to plan sand through the cover glass until it is paper thin,

place inverted onto a piece of tape, and remove the unit from tape. The cover

glass should remain on the tape. During this technique, the CCD must be removed

from the board prior to sanding to avoid damaging the support components.

Debris has been the main problem with all opening techniques attempted to date,

with the sanding method being the cleanest, but also, the more tedious and difficult to complete. With relatively

small areas of laser damage, it is difficult to differentiate optically, even with the use of a wide variety of lighting methods,

between the mechanical damage from debris and laser damage. If possible, the damage sites are best identified and

documented prior to removal of the clear protective glass. There are several

variables that influence the quality of photomicrographs such as, damage size,

focal distance and lighting that can, under certain circumstances, make photo

documenting the damage unsuccessful.

Optical inspection

Optical macroscopic

inspection is utilized to correlate the laser shot damage to the video image output. For this step, it is important

to have as many details about shot locations and energies as possible. Locating and accurately identifying the

laser shots will allow for the photomicrographs of laser shots to be correctly

identified for comparison of the damage on the die surface to the failure mode

of the video output. All laser shots are photographed on a high variable power magnification microscope and overall

images of the CCD are photographed using low variable power microscopes. As with

the initial video output of the device, various lighting conditions, including

bright field, dark field, and polarization, are used to optimize inspection and

photographic documentation to maximize the information available from each site.

Electrical

Measurements

Volt-ohm

meter and curve tracer measurements are made on the pins of the device with and

without light. Testing on functional, nonfunctional, and damaged array CCDs has

not yielded much useful information. However, on-chip probing of undamaged and

damaged circuitry using a curve tracer or volt-ohm meter, especially after laser

isolation of portions of the circuitry, is instructive and useful. On chip

probing often assists in the understanding of the laser shot damage, whether it

be to poly-silicon gates, or more extensive and invasive

damage.

Probe/Laser Station

The laser station is utilized to

remove the topcoat on the die surface and allow access to the underlying

circuitry. Selected elements, metal or poly runs,

are then removed from the circuitry with the laser to simulate failure

modes and verify by electrical measurements

the different hypotheses for what conditions are present to cause the resulting

anomalous video outputs. This testing is performed while the device is under

power to allow monitoring of the video output during the isolation

process.

Component Preparation

Before cross section or angle lapping, the CCD device must

be removed from its board. The preferred technique is to use a low temperature

hot gas solder process to allow removal of the device being evaluated without

damaging surrounding components. There are circumstances that require the

device to be reinstalled on the board for further optical and functional

testing. This is accomplished with the same hot air flow soldering

process as removal. The isolation or damaging of

selected pixels in the array or other chip circuitry to simulate or duplicate

the behavior and damage that a CCD had upon receipt for failure analysis, can be

completed while the CCD is mounted on the board.

Package, Glass, Die,

Organic Identification, Removal & De-processing

Once all of the needed information

has been obtained from the CCD assembly and CCD device, the cover glass is

removed to allow further analysis by FTIR, SEM-EDS, and

Transmittance/Reflectance. Identification of the epoxy that holds the cover

glass can be identified by FTIR. Once the CCD chip-die has been removed, the

organics over the array can be identified by FTIR. Plasma etching, using O2,

has been found effective in removing the array’s cover coat, microlenses,

planarity layer, dyes, and other organics to expose the metallization,

polysilicon, and oxides above the silicon. The SEM-EDS can identify the

metallization and glasses used on the die. Normal chemical methods can then be

used to remove the insulating glass, metal, dielectric insulation, polysilicon,

etc, to gain access to the silicon surface.

SEM Inspection/Analysis

The areas identified and photographed

during optical inspections are typically submitted for SEM

analysis,

secondary, or backscatter, electron imaging,

Energy Dispersive Spectrometry (EDS), ‘point’ or area elemental spectra and

maps. Depending upon the depth and severity of the damage to the die, the SEM

photos give a much better image of the damage versus the optical

microphotographs. The SEM imaging, together with optical imaging, can also

provide indications as to the depth of the damage, whether surface, subsurface,

etc. The use of SEM-EDS permits the identification and elemental mapping of the

damage sites, which provides additional information about the cause of failure

or anomalous chip behavior. The SEM is

also utilized after beginning the cross sectioning. The sample can be

periodically viewed and documented during the entire sectioning process with much higher

resolutions than available with the optical microscopes, providing higher

magnification images, elemental identification and maps of the materials in the

areas of interest. The SEM inspections also provide additional information to

confirm or refine the theories of what has been damaged and why such damage

causes the chip to have the observed anomalous functional

behavior.

Cross Section, Angle Lap/Plan Section/Deprocessing/FIB/and

Staining

Cross sections of various types are very useful in confirming

and understanding the CCD circuitry, gate and cell array structure, and

composition. On a functional or damaged device, de-processing is accomplished

by utilizing a Plasma Etcher to remove the organic cover coat, lenses, planarity

and dye layers. Wet chemical processes can then continue the removal of glass,

metal, interlayer conductor glass, polysilicon gates, etc. down to the silicon

die. Cross sections perpendicular to or at a very slight angle with respect to

the side, just off the row and column line of the array will permit visibility

of the layers in-situ of the whole cell structure by moving along the section.

Staining of the silicon, which etches diffused, implanted, epitaxial and other

regions to a different degree, depending on the dopant impurity level, provides

visibility into the subsurface silicon structures. Perpendicular cross sections

at a 45 degree angle with respect to the array matrix can be used to provide

additional information on exact locations of the structures, particularly

damaged sites. For further clarification, a very shallow angle lap with respect

to the chip surface provides a magnification in the vertical direction and with

staining, can help clarify substructures. Inspection and documentation at

appropriate layers of each of the above sections or deprocessing levels by

optical, SEM, SEM-EDS spectra and elemental maps, permits complete understanding

of good and damaged areas. Due to its fine control compared to

mechanical-chemical sectioning, FIB sections of good and damaged areas provide

an additional, more refined view of the structures as needed.

Failure Analysis and Fault

Isolation

The

initial CCD was received in a nonfunctional condition. The device was subjected

to 10 laser shots of increasing energy, at an angle with respect to the surface

of the array. The entire die was inspected optically and photographed to

identify the array area, controlling poly silicon gates, parallel and serial

shift registers as well as the clock, gate drive, and power circuitry. An

electrical schematic was derived to help gain an understanding of the device’s

normal operation. This process also provides background information to assist in

exploring how the laser shots created a particular level of damage, either

causing local pixel malfunction, row or column problems, combined problems or

total device failure.

Image 1

High magnification photograph of the laser damaged

area.

The

chip was removed from its package and then divided in half via diamond sawing.

One half was utilized to successfully remove the organic cover-coat, lenses,

planarization, metallization, and insulating glass layers to gain access to the

underlying pixel structure. A portion of the other half was subjected to a very

shallow angle lap to clarify the gate interconnections and structure of the

array. Chemical staining of the pixel area was employed to highlight the

subsurface implants and silicon diffusions. The sample with the 10 laser shots

was cross-sectioned at 90 degrees successively into several of the laser shots

closest to the edge of the chip. Inspection of the laser damaged areas, both

optical and SEM provided additional information about the construction of the

array. The information obtained from the physical layout, optical and SEM

inspections, and SEM-EDS analyses permitted the reconstruction of the active

pixel area in the silicon array. Correct placement and alignment of the

polysilicon gates, light protecting metallization, dye and lenses confirmed

construction of the array elements.

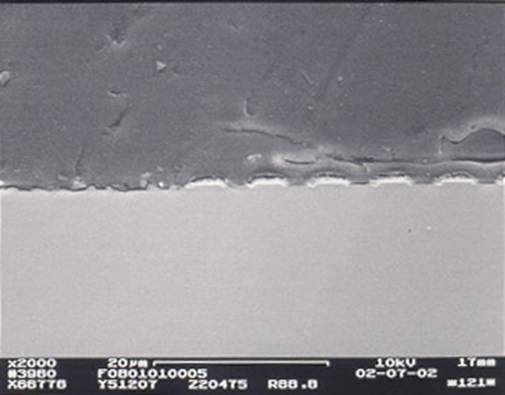

Image 2

Representative cross section of die

structure

The 90 degree

cross-sectioning process of the die was continued into the center of the final

laser shot which caused the device failure. Optical, SEM, and SEM-EDS analyses

of the sectioned unit in the area of the laser damage and outside the laser shot

area, where the device was undamaged, confirmed the hypothesized relationship

between the die structures and the pixel sketch showing that the device’s array

components were as expected.

In the area of the 10th shot, the

inspections confirmed that the clear coat, planarization layer, lenses, and

cover coat had been vaporized. The inspections and analyses also clarified that

the dual metal, aluminum over tungsten, light shield had been melted into the

polysilicon gates and into the silicon surface shorting the channel stops to the

pixels and possibly into the substrate beneath the epitaxial area. The melting

of the metal light shield into the silicon is shown on the SEM photomicrographs

and SEM-EDS and confirmed by the absence of metal above the polysilicon gates.

Damage exhibited at the failure site is typical of the extent of damage that is

sufficient to kill a semiconductor FET. Although no isolation or probe station

electrical measurements were made, the metal and polysilicon to substrate shorts

were clearly adequate to prevent device operation.

Image 3

Cross section of

laser damage

Inspection of the laser

shots from the top of the array and from the cross sections show the energy

distribution of the laser beam shots as they hit the array. The more significant

damage was at the center of the shot with less damage moving outward from the

center, reaching the edge of the beam where there has been essentially no damage

to the organics surrounding the laser shots. The cross section into the

5th laser shot shows vaporized and disturbed organics, but intact

metallization and polysilicon, confirming that the first 9 shots did not have

sufficient energy to melt the light shielding Al-W into the silicon, which would

cause complete disruption of functionality. The first 9 laser shots compromised

the pixels where the surface organics, dye, planarization layer, lenses and

cover coat had been removed or disturbed which would have eliminated the color

and light gathering ability of the affected pixels. However, as long as the

light shielding metal, polysilicon gates, and inter-metal/poly dielectrics

remained intact, the pixels not affected by disturbance or removal of the

organics would have (and had) continued to function normally, together with the

rest of the device.

FTIR spectroscopy was

used to identify that the array cover coat is acrylate polymethylmethlacrylatic,

and using subtraction techniques that the lenses and possibly planarization

layer, are Teflon based.

The cyan, magenta,

yellow, and green dye over the pixels beneath the lenses had insufficient

material to identify their composition. There was a test pattern of the

complimentary color and green dye matrix on metal, but the individual dyes were

the same size as those over the pixels, preventing the analysis of their

individual compositions. Complementary color dyes are used instead of primary

colors so that more light is available to the silicon’s pixel photon detectors

for increased sensitivity.

A second unit

received 36 laser shots of increasing energy in the nano/pico/femto second range. The induced damage was insufficient to

cause total failure of the device, allowing for a more detailed investigation of

the video output verses the level of damage to the die structure. The laser

shots were perpendicular to the surface of the die and had a very narrow

diameter, a few pixels, or in some instances, only a single pixel was

affected. Approximately 27 of the 36 shots were detectable by optical

microscopic inspection. However, the number of damage sites visible when

operating, varied from less than 27 to more than 27, depending upon the angle

and intensity of the applied light on the array.

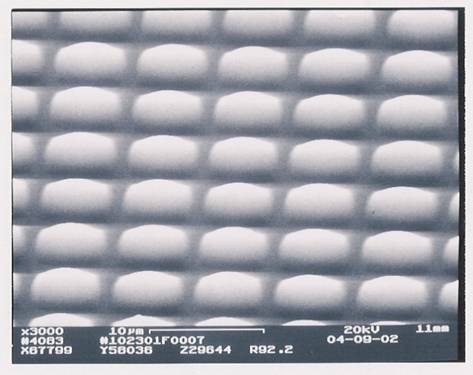

Image 4

Optical microphotograph of laser shot

damage

Inspection of the damaged

spots using high magnification microscopes indicated that the laser had

disturbed either the dye, planarization layer, or micro-lens depending on the

shot energy of the damaged area inspected. With increasing energy, a

corresponding increase in the depth and severity of the disturbance was observed

in one or more of the layers. To observe the extent and location of damage it

was necessary to continuously vary the focus and mentally reconstruct what was

being seen into a three dimensional image. While small sections of

metallization could be seen on selected spots, there did not appear to be any

significant damage to the metallization.

With a

focusing lens attached to the CCD, the camera board produced a nearly normal

image, except at the small laser damaged areas. Different colors of light or

dark appeared, depending upon which pixels, how many pixels, the amount of dye

disturbed, and the amount of damage to the pixels’ micro-lens as well as the

interpolations of the camera board’s image (and pixel) adjusting algorithm

electronics.

A small

diameter light beam from a high magnification microscope that is co-axial with

the optical axis was slowly moved near the edge of the dim, dark, or colored

damaged spots. When the light was applied, the damaged spots would output a

light level corresponding to or exceeding that of the undamaged pixels around

the spots. This confirmed that the damage did not extend down into the

metallization, polysilicon, dielectric isolations, or silicon, where the light

was being ‘properly’ transformed into an electrical charge. Without the

addition of the higher intensity light, damage to the dye, planarization, and

lenses deflected, absorbed, or reflected the ‘normal’ light in which undamaged

pixel areas functioned correctly.

Image 5

SEM photo of laser

damaged area

Of interest at the laser

damaged spots, visible by optical or functional malfunction, was that SEM

secondary and backscatter electron images at various acceleration potentials and

at various magnifications were unable to detect any difference in the cover coat

or lens shape over the damaged spots compared to undamaged spots. This finding

together with the observations made above, confirmed that the damage or

disturbance was localized to the organics between the cover coat and the

dielectric layer covering the light shielding metallization and silicon. Even

the highest energy shot area was indistinguishable from fully functional pixel

areas.

A third unit was laser

shot 38 times with 24 of them optically visible. The range of energies was in

the nano/pico/femto realms. As with the previous units, varying the light type,

angle, shading, etc. caused some of the spots that were not operationally

visible to become visible. This suggests that the lower energy shots did

disturb the organics, but that light perpendicular to the array was not the

angle at which the light was attenuated the most.

The first 14 of the 38

shots did not output light when the unit was not illuminated. This was due to

the lower energy shots not causing damage down to the silicon, but instead the

damage was limited to the organics. In fact, there was so little damage on the

first 14 shots, that no evidence of damage could be detected on them with

extensive high magnification microscopic inspection in the exact locations of

the shots.

The next 24 shots did

exhibit light output, even when the unit was not illuminated. This was probably

due to the damage reaching the lower portions of the structure, including the

dielectric-silicon interface, causing charge injection, which the unit would

shift out even when under total dark conditions.

Comparisons of the last

24 shots show an increasing depth of damage and a slight increase in the number

of pixels involved. The light or absence of light output, from the damaged

areas, also relates to where on the pixel the highest energy of the laser pulse

struck, as well as the other factors previously mentioned during discussions of

other units.

The device did not

exhibit any of the horizontal black lines seen on the previous devices. The

main reason for the absence of the black lines is that these laser pulses have a

much tighter, narrower energy distribution so that the sides of the damaged

areas tend to be vertical rather than sloping as with the broader energy

pulses. These narrow laser beams tend to cut the polysilicon gates cleanly and

do not short them to adjacent layers of the light shielding metal or substrate,

compared to the shallow sided crater cuts with broader energy distributions

which were more likely to permit shorting of the polysilicon gates to adjacent

conductive layers, causing the horizontal black lines.

Inspection of the highest

energy shot 38, which is also the deepest as seen by comparison of damage

depths, indicated that the light shielding metal has melted into the silicon

substrate. The metal contact, as with the previous unit that exhibited column

blooming, caused the deposition of charge into the column, or columns, in excess

of what the gate voltages and electronic shutter could control.

Enlargement of the

operating unit’s image without light reveals the blooming column either had

several columns damaged by the laser shot or that the primary blooming column

has sufficient excessive charge to over-ride the channel stops’ voltage fields

and spill charge into adjacent columns, the left being blue-ish, the right being

white-ish. Of interest is that the adjacent columns do not have continuous

charge accumulation, along their columns. Rather, the blooming in the adjacent

columns appear to have every other pixel ‘light’ and the ones in between dark,

or normal. That phenomenon is most likely due to the way the CCD reads out

alternate fields, during which every other vertical pixel is kept ‘off’ by the

gate and the adjacent gate kept ‘on’ until the next field, after which, the

process is reversed.

The vertical transfer of

charge is from the bottom to the top of the screen in this image. Thus, the

enhancement of the blooming, greater light intensity, and color change of the

columns from blue-white-white to green-yellow-orange, is most likely due to a

build up of charge as the vertical control gate pump the charge to the

horizontal shift register together with affects due to the units control board

electronics. If it were due to damaged columns and channel stops, one would

expect the phenomenon to be at or near the damage site, which is causing the

problem.

Upon closer examination,

spots 24 through 38 also exhibit blooming into adjacent pixels but only on the

row(s) where the primary pixel damage has occurred. As with the whole column

blooming, the single or a few pixels, blooming is most likely due to a local

disturbance of the channel stops that lets the charge bleed over into the

adjacent column.

As with the other units,

operational behavior of the device with a focusing lens produces a normal image

over the whole array except in the damage spots and along the blooming

column(s).

A fourth device received

11 laser shots, spaced so that there was no overlapping of the rows or columns

affected by the damage. This was beneficial for the clarification of damage and

allowed for a more definitive failure analysis of the individual

shots.

Functional video images

from this device produced normal images except in the circular areas of the

laser damage. There were three exceptions to this general observation. One

shot has one or two dark rows extending from both sides of the spot and becoming

less dark the further from the center, until the rows appear the same as those

that were fully functional. The highest energy shot produced an essentially

identical dark line radiating from both sides of the center crater. In the area

of the dark horizontal lines, no video information was obtainable from the

related pixels when capturing an image, even though the dark lines did pass

information through the dark line. The dark horizontal lines relate to the

center of the craters where the highest energy and damage occurred. The damage

in the center of the two craters shorted the metallization to the underlying

polysilicon gates. Light striking the pixels associated with the dark lines was

still causing the generation of hole-electron pairs. However, because the

voltage on their related gates was shorted, the electrons were not stored and

those pixels appear dark, as if no photons had struck the photo detectors. The

relative high resistance of the polysilicon gates, compared to aluminum,

permitted the gates in the center of the laser craters to be ‘shorted’ by metal

yet because of their relative high resistance the polysilicon gates away from

the craters had sufficient voltage to store electrons from the photon generated

hole-electron pairs.

The bright vertical lines

originating from the highest energy laser shot, are caused by the vaporization,

melting and shorting of the metal light shielding mask through the dielectric

and into the silicon of the columns, bounded by channel stops, injecting charge

into the columns, causing blooming that masked any hole-electron pair generation

and storage in those pixels, preventing them from producing the image from these

areas.

The damage craters

related to the laser shots on this part exhibit an increasing amount of concave

ablation of organic material with the corresponding increase in laser energy.

This unit was also

examined using the IR microscope with negative results. However, when this part

was examined in the Emission microscope, three of the craters displayed light

emission because of the loss of some of the electrons’ energy as or after they

traversed the damaged oxide. This confirms that the shot had caused damage at

least down to the dielectric above the metal and silicon and probably into the

silicon. It is interesting to note that one shot did not exhibit any light

emission. However, the organic damage could be blocking areas where there are

oxide problems shown by the electron energy loss, in the form of light, or that

the crater in question did not experience the same severity of damage to the

oxide. It is also interesting that one crater did not exhibit either a black or

white line fault. But, that also can be explained by the probability that the

energy dissipated in the crater just happened to not involve either the

polysilicon gates nor the silicon columns in the same way that the shots did in

the other two craters.

Without further analysis,

isolation and measurement of the polysilicon gates to other structures, it would

be difficult to determine how many gates are involved in the dark lines and how

many columns are involved in the light blooming. A single column could be

involved, if it had sufficient charge or connection with the channel stops, or

several columns could be brighter because of the overflow of charge from the

primary column short into adjacent columns.

A fifth

unit had received 9 laser shots with energies from the nano/pico/femto realms.

When the camera is operated with ambient laboratory light, 2 to 4 of the spots

can be seen, depending upon the lighting or shading of the array. The visible

spots appear as colored dots of light, or dark spots. With a lens mounted to the

device, the rest of the array when in light is fully functional. During

operation in complete darkness, four or five of the nine spots were visible in

the video output.

Optical inspection of the

spots with both low and high magnification microscopes, show different amounts

of damage to a varying number of pixels, depending on the energy, time realm,

and exact location of the center of the laser shot with respect to the array

structure. The video image is affected differently depending upon whether the

laser strikes on metal between pixels beneath the lenses, or on the silicon and

dye coating, as well as the amount of energy and diameter of the laser beam.

Inspection of the remaining spots that did not produce functionally visible

anomalies, revealed no optically visible damage. The spots were visible in the

video output because the clear coat, lenses, planarization layer and/or dye, had

been disturbed sufficiently to cause the laser damage to adversely affect the

light path compared to undamaged pixels.

The fact that the

damage spots were also visible when the unit was functioned without any light

indicates that the laser damage had also disturbed the dielectric-silicon

interface or the slightly-sub-surface silicon, so that the damage caused

hole-electron pairs to be generated, the electrons accumulated, stored and read

out as if photons had impinged those spots.

Because the other 5 spots

could not be seen during functional operation, in light or dark environments,

nor by high magnification microscopic inspection indicates that those spots did

not incur sufficient damage to be detected by the device or its board

electronics reconstruction algorithm.

As with the previous

units, except the initial killed device, this unit could have polysilicon gates

related to the spots checked for resistive shorting by isolation, electrical

probing, and measurement related to other structures. This could be followed

by appropriate FIB sectioning and FIB-EDS to confirm the location and severity

of the damage caused by the laser shots.

A sixth

unit received 27 total laser shots with all shots in the nano/pico/femto realm.

Operation of the unit with lens showed ~12 shots of varying size and color.

Also seen were several adjacent vertical blooming columns that had minor

horizontal blooming, without an image, just at a given level of light. With no

light, the horizontal (left) ‘light’ blooming from the blooming column had two

overlapping areas, with the closer area being slightly brighter than the further

one.

Finally, a

most interesting blooming column(s) was observed that had an operational, image

producing section between its lower and upper blooming portions of the column.

This is the first column found that did not bloom its full length, preventing

any image production from that column. With this column, the bottom ¼ of the

column bloomed with a triple of different colored spots at its top. The next ~

1/3 of the column produced an image even thought the top 42% continued to

bloom. One would expect that with the top portion of the column blooming, which

is nearest to the horizontal serial readout shift register, that any signals

coming from the operational pixels (between the blooming column) that had to

‘pass through’ the blooming column to reach the output shift register would be

masked by the blooming of the column. However that is clearly not the case.

Initial

attempts to explain how this phenomenon could occur were frustrating and

frustrated. It caused a re-thinking of exactly how a CCD moved charge from its

array to its output and finally to the screen.

Because

one sees a constant image from the CCD-board-camera, an impression and

conclusion is easily, but mistakenly, made that the charge is not being read out

in frames with the electronic shutter acquiring photons for a fixed time

period. However, the reason the CCD does read an image from the middle

operative length between the column blooming at each end is that the blooming

has not consumed the column. There is a lesser charge level than fully blooming

columns, which permits the pixels in the middle between the blooming portions to

acquire photons/electrons/images normally. Once the electronic shutter ‘closes’

and photon/electron acquisition stops, the vertical shift registers move the

frame of pixels, row by row, into the horizontal shift register and output.

Thus, the operative pixels in the column do not really have to move through the

blooming column to reach the horizontal register and output.

What is

interesting, is how the signal from pixels on the opposite side of the

horizontal shift register read their signals out, the same mechanism is

operative. However, the more common full blooming columns had confused the

issue since they had sufficient damage and enough charge to overwhelm all of the

pixels in the column.

Several

additional anomalous phenomena were observed when watching the image produced

during CCD operation and light conditions varied with the view or the unit was

pointed at an even field of light that was then decreased till no light reached

the array. The fully blooming multiple columns had sufficient damage to spill

into adjacent columns and increase the length of blooming in the adjacent

columns with increased light intensity on the array. There was also a

translucent appearing lateral ‘waterfall’ to the left of those columns with

ambient light. However, with no light reaching the array the translucent

‘waterfall’ becomes much more visible, although it was still not bright and the

single one that was slightly visible in ambient light becomes two, one

overlapping the other.

A seventh unit received 9

laser shots in the nano/pico/femto realm. The 9th shot caused the

part to become non-functional. DC measurements on each of the failed CCD’s pins

yielded essentially the same values as the pins of a fully functional device.

The failed and fully functional CCD’s were removed from their control

electronics boards and switched to the other CCD’s board. The failed CCD

remained non-functional giving the same no output as it had on its initial

board. The units were returned to their own boards and again, as expected, the

failed CCD provided no output and the fully functional CCD again was fully

functional confirming that the control electronics were not involved in the

CCD’s failure.

Optical microscopic

inspection of the 9 shots confirmed that the damage on the CCD increased with

each increase in laser energy. High magnification inspection of the

5th shot showed that the spot had damage similar but greater in depth

than that of the last shot on T0002 which had vertical column blooming. SEM/SEM-EDS inspection of

previous damage on other failed parts indicated that the laser had vaporized the

organics and melted the light shielding metallization into the substrate as well

as melting the silicon photo detectors to the underlying silicon and channel

stops. The level of damage was sufficient to prevent the operation of the

device by essentially shorting the light shielding metallization, polysilicon

gates , photo detectors, substrate implant, P-well, P+ channel stops, and N

substrate which reduced on-chip voltages to ineffective/inoperative

levels.

Confirming the failure

and determining the exact cause of failure at spot 9 would be accomplished by

isolating the polysilicon gates related to the damage area, and electrically

microprobing from them and the light shielding metallization to the on-chip gate

outputs, on-board bias generator, substrate and power supplies. The DC voltage

levels of the failed and fully functional CCD pins indicate that the control

electronic board voltages were still functional. Complete verification that was

the case would be done by measuring the failed and functional CCD pins with an

oscilloscope with sufficient digital memory depth to confirm that the control

board electronics signal levels and waveforms were the same.

Further analysis that

would provide additional confirmation would be SEM, SEM-EDS spectra and

elemental maps of spot 5 and spot 4. And, FIB followed by organic plasma

etching, silicon decoration, and SEM, SEM-EDS of both ‘kill’ spot 5 and

‘non-kill’ spot 4, for comparison.

An eighth

part has 4 types of anomalies from the laser shots. It is interesting that all

16 shots can be seen on the video output of the device when the array receives

no light. And, that 11 to maybe 13 are visible when the device is operated in

the light. As with the previous units, variations in light and shading on the

operating device caused changes in the appearance of the spots and also caused

changes in the green waterfalls.

Several

of the types of damage have been seen and explained on previous devices. The 3

black horizontal lines, with a white line above and below the dark lines have

been previously discussed. Here, the damage is a bit more severe, covering a

greater number of gate sets, which most likely gives rise to the ‘bracketing’

white lines. Additional work will be necessary to properly address the cause of

the white lines. However, it could well be an artifact of the decoding

circuitry algorithm of the CCDs control board electronics.

The

16/11-13 (‘small’) spots down the left hand side of the device are related to

previous spot damage and the several different spots can be explained with a bit

of additional information. The vertically elongated spots with the unit under

both dark and light conditions are a bit different than the other spots on this

part and on previous parts. But, it is really a matter of degree. Here the

longer vertical spots have damaged more pixels vertically than previous damage

spots, thus, they appear as streaks instead of spots. Optical low and high

magnification microscopic inspection of the 5 greater elongated spots confirmed

that the laser damage with larger circular area at increased energy,

corresponded to the greater vertical, and horizontal, number of pixels that were

damaged, hence the length and width of the line.

Viewing

the video of the unit taken after the laser shots, with the filter in place, the

3 black lines appear white and there is a very narrow [probably a single column

instead of the multiple columns seen on the other units] vertical column

blooming from the 2nd large spot down to the bottom of the screen.

There is also a ‘split’ narrow [single column] blooming column associated with

the 5th large spot. Neither of the column bloomings were as clearly

seen when the unit was operated and its output recorded at Crane. The single

columns were occasionally visible, but just for a short time. Thus, the

lighting conditions, intensity, wavelength, angle, presence of filter, and lens

determined whether and how visible the two blooming columns were when the device

was operated.

An inspection of the

optical photomicrographs of laser shots numbered 1 and 5 indicate that the

damage to the device was from the light shielding metal melting down to the

substrate, or damage to the dielectric-silicon interface, silicon of adjacent

(vertical) pixels, and local damage to channel stops so charge could spill to

adjacent columns but only for a portion of the column.

The green ‘waterfalls’ do

not prevent images from ‘beneath’ them from reaching the horizontal serial

output register that is at the top of the image. That is clearly seen when the

unit was operated with the blue filter and focusing lens reinstalled on the

device and images of the lab were taken. The images in the green waterfalls are

blurry and somewhat distorted but can easily be recognized. And, with the unit

with blue filter and focusing lens removed, placed in a micro probe station and

a tungsten probe moved over the array into the second waterfall, again, the

probe is slightly blurry but easily seen. In both cases, whether views of the

lab and the position of the probe, the acquired image [pixel charges] of the

probe had to traverse the waterfalls and the dark row lines to reach the

horizontal output serial register, which is at the top of the image with its

output on the left, and visible on the video monitor.

The size of the damage

corresponded to the energy level of the laser shots. Thus, we are left to

explain the 5 ‘long’ vertical white-yellow-black outlined shots and the 3 green

waterfalls and should probably address the apparent discontinuities in the

bottom two black lines within several spots along the green

waterfalls.

-The

waterfall effect was created due to decreased gate voltages and stray

substrate.

-The charge transfer efficiency is decreased. However, pixels

within and outside the waterfall are receiving the same amount of

charge.

-Shorting

the gate or cover metal to the charge well caused white vertical lines, which

creates an overload of charge that the CCD cannot handle, thus the blooming

effect occurs.

-Notice that areas between the light lines were still

behaving properly due to channel stops remaining intact.

-Failure modes are typically a result of the depth of

damage caused by a specific laser shot and the laser’s exact location in a

pixel/group of pixels.

-The diameter, location, focus, and

energy of the laser beam are also critical.

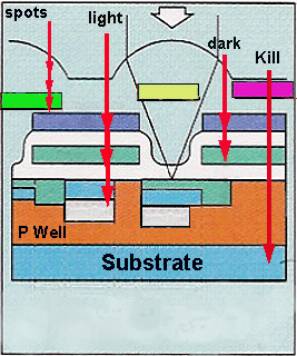

Figure

1

Figure 1 above highlights some of the locations/positions of the laser shot within a

pixel (or group of pixels) and which layers/surfaces are damaged or shorted to

the next underlying (or adjacent) layer cause the damage seen on the video

output.

Summary of Failure

Theories

Theories of

Failure

Once

the cell structure, array, chip schematic, on-chip circuitry, physical layout,

and drives/controls/algorithms/output controls from the PWB controller are

known, the video output of a functional and an anomalous CCDs response to light

and dark can be analyzed. Failure theories are established, refined, and confirmed by

looking at many different data streams, including, but not limited to the

following:

-Electrical measurements and characterization of the

device

-Visual

CCD-board output (video screen) responses to the laser shots

-Measured

and visual response to zero light, low through high level microscope and laser

light, etc.

-Knowledge

of laser spot size, shape, energy, time range, (and wavelength) per damage

site

-Understanding of individual damage sites via selected optical

microscope(s) and various mode and light exposures

-SEM

inspection, including SEM-EDS spectra and elemental maps,

-Layer by

layer deprocessing of the array

-Cross

sectioning of the various damage sites

-Shallow

angle lap with decoration/staining

-FIB

cross-sections in vertical, horizontal, and 45 degrees of characterized damage

and undamaged sites, if available

-Emission

microscopy of failure sites

-Scanning

capacitance probe

-Other analytical method outputs as appropriate

Literature,

seminal and other textbooks, manufacturer’s part data, university, and research

web sites and patent searches augmented CCD cell structures, lenses, circuitry,

and operation. Combined with the data listed above, failure hypotheses were

devised for the cause of the anomalous behavior. With the hypotheses and

theories thus devised, methods to test, refine, refute, or prove the theories

can be devised. Methods include duplication or simulation of the failure by

physical, mechanical microprobe, laser, light or chemical methods on functional

units.

Explanation of Chip

Failure due to the 10th shot

-SEM results showed that metal and

poly had been vaporized and melted to the substrate at the center of the damage

area.

-Extent of damage caused a low

resistance short of metal to the gates, the substrate implant (n-) and p- and p+

channel stops.

-The short pulls the gate voltages

down to ineffective and inoperative values.

-Shorting of the implants and

diffusions loads the power to the unit disturbing (lowering) their values and

preventing device operation.

-Vertical shift gates, horizontal and

output sense amplifiers are inoperative.

-Concentration of varying degrees of

light on laser spots causes dark spots to “disappear” on video

output.

-Indicates that damage is limited to

dye and lens material, not underlying glass/metal/gate structures.

Hypothesis: energy wavelength did

not disturb overcoat layer and instead damaged dye and lens material

underneath. The overcoat layer acts as a barrier to viewing damage when using

SEM.

Horizontal dark lines adjacent to and on each side of laser

spots 8 & 11

-Radiate along a gate or two for some

distance and are darker at the damage circle and lighten further away from the

damage area until normal function resumes as the operating voltage gets closer

to normal levels.

-The 4 phase poly gates are powered

from each end of the array and are individually continuous.

-Dark lines of the gate polysilicon

shorted at the damage circle run perpendicular to the channel stops and cross

some 30 to 50 channel stops (which define the vertical serial shift register

width and thus pixel width).

Explanation of dark lines on CCD output

-Laser energy melted metal to the

underlying poly gates causing a resistive short within the damage area (poly

gate is more resistive than aluminum).

-Thus, with applied power to both

ends of a resistively shorted gate(s), a variation in the dark line (darkest at

the damage circle) is expected.

-Can verify this theory by isolating

gates and performing curve tracer measurements from the 4 phase gates to ground

and the 3 power pins.

Explanation of lighted column

-Emission Microscope results indicate

that emitted light was at a higher level on spot 8 than any other spot (also hit

with the most laser energy).

-SEM photos indicate significant

metal damage (center of damage area - worse than other spots).

-Spot 8 also exhibited “dark line”

damage.

-Damage suggests that the metal and

poly gates have been melted into one or more of the vertical serial register

columns.

-Metal and gate(s) are making

electrical contact with the n- and p- (and probably p+) channel stops that

define the column(s).

-Voltage on the cover metal or gates

therefore is resistively shorted to the substrate in the affected vertical shift

registers defined by the channel stops.

-The cover metal or gate voltages cause charge injection in the

affected vertical shift registers at the damaged area so that the column’s pixel

signals all appear to have accumulated a significant amount of light greater

than the rest of the

array.