Download the PDF file

This section describes failure mechanisms and

anomalies of microcircuits. Use this section as a guide to design and select

microcircuits.

Failure Mechanisms - General

Microcircuit manufacturers have long since learned to

control and reduce failures in their wafer fabrication and hermetic package

processes. However, the plastic encapsulated microcircuit (PEM) processes are

still maturing with some problems still not controlled as well as users would

like. The military now allows the use of consumer, industrial and automotive

microcircuits in applications. Since PEMs are fairly new to the military, their

reliability and performance over time remain the subject of scrutiny by both the

manufacturers and users.

Consumer-grade PEMs are the riskiest microcircuit

products used by the military. The main areas of study regarding their use are

their unique failure mechanisms. Until studies are complete, designers should

continue to monitor these parts and not assume there is complete freedom to use

any microcircuit in any environment without concern for reliability. The risk

should be minimized and the parts should still be monitored. Both producers and

users in the military marketplace should know the potential failure mechanisms

and anomalies of each microcircuit they plan to use. Because of the newness and

risk PEMs place on the military industry, this section describes them in more

detail.

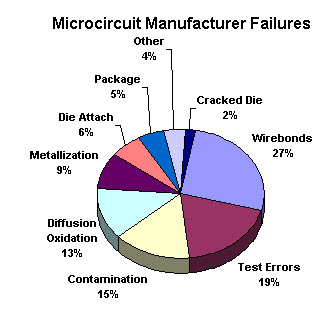

Figure 1shows recent failure mechanism breakdown data for packaged die at microcircuit

manufacturer facilities.

The Naval Surface Warfare Center, Crane Division has

been periodically assessing PEMs for over 25 years. For an example, they

recently assessed over 3,000 PEMs for Trident Fire Control, Trident Navigation,

CEC, Army Tank Command (TACOM), and the NAVSEA Parts Reliability and Derating

Manual Programs from 1997 through 1999. Figure 2

shows the number of failed, marginal, and passing PEMs during this assessment

period. The more common failures and anomalies found during this assessment are

(1) improper moisture-sensitivity-level of package, (2) contamination, (3) poor

die-paddle construction, (4) poor wire-bonds, (5) voiding, and (6)

delaminations. Having 30% of the total microcircuits either failing or being

marginal enforces the obvious need for PEM assessments and

monitoring.

Figure 1. Microcircuit

Manufacturer Failures

Source: ICE, “Roadmaps of

Packaging Technology”

Figure 2. PEM Assessment

Results

Source: NSWC-Crane Division

Table 1 and Table 2 cites some of the more common microcircuit failure mechanisms and anomalies with

their probable causes.

|

Type

|

Example

|

Most Likely Cause

|

See Figure

|

|

Chemical

|

1. Corrosion

2. Contamination

3. Dendritic

Growth

4. Metal Migration

5. Intermetallics

6. Oxides

|

Moisture and Ionic.

Poor process control by

MFR.

Moisture, Bias, and exposed metal.

Current density in Al metallization.

Inter-reaction of dissimilar metals E.G. Al-Au

(Purple Plague).

Metal exposed to oxygen.

|

12

9

14

13

|

|

Physical

|

1. Open Circuit

2. Short Circuit

|

Loss of bond/wire integrity, or cracked die from

overstress by Thermal/Mechanical Shock, or Vibration, or weakened interconnects

from Bond misplacement and from Corrosion/Electro Migration. Loss/weakening of

wire-bonds from sweep during injection of molding compounds.

Particle or interconnect wire, metallic migration,

dendritic growth-poor process control.

|

6

|

|

Function

|

1. Loss or Degrade

|

Electrical Overstress, ESD, Radiation, High

Resistance Electrical Contact, High Temperature Exposure.

|

|

Table 1. Failure Mechanisms:

Die/Interconnects

Chemical Failure Mechanisms

Historic chemical failure mechanism concerns with

hermetic seal microcircuits also apply to PEMs; for example corrosion,

contamination, dendritic growth, metal migration, oxides and intermetallics.

PEMs are even more likely to develop "Purple Plague" because of the wide use of

Aluminum (Al) and Gold (Au) in their wire bond fabrication. Although PEM

manufacturers now use greatly improved encapsulant, additives such as bromide

(fire retardant) can introduce halogens which produce corrosion when combined

with moisture - all plastic encapsulates absorb moisture. PEM manufacturers now

use encapsulants with additives such as bromide (a fire retardant) which can

introduce halogens that produce corrosion when combined with moisture. All

plastic encapsulants absorb moisture and improperly cured encapsulants can

result in excessive porosity and moisture absorption.

Improperly cured encapsulant can result in excessive

porosity and moisture absorption.

|

Type

|

Example

|

Most Likely Cause

|

See Figure

|

|

Chemical

|

1. Corrosion

2. Porosity/Pin Holes

3. Solderability

4. Marking

|

Salt or Harsh Atmosphere.

Poor cure of Encapsulant by MFR. (Encapsulated IC);

Inferior grade of metal (Hermetic IC).

Poor finish by MFR. or Harsh Atmosphere.

High Temperature Exposure, Harsh Atmosphere or

Cleaning Agent.

|

10, 11

1, 15,

16

|

|

Physical

|

1. Leaks

2. Rupture -

“Pop Corning”

Delaminations

3. Lead Seal

|

Poor weld or braze by Mfr., Fatigue by Thermal/

Mechanical Shock or Vibration (Hermitic seal IC).

Absorbed moisture expands during solder operation

(Encapsulated Packages), poor process control, Thermal Shock (Encapsulated

Packages).

Poor process control of Lead/Package seal by MFR.,

Mechanical Fatigue from Vibration to Temperature Cycling. (Both Package

Technologies).

|

2, 3,

4, 5,

7,

8

|

Table 2. Failure Mechanisms:

Packages/Leads

Physical anomalies occur from other additives used to

tailor package characteristics, e.g. hardness, temperature coefficients of

expansion, and heat dissipation. When these additives are segregated from

inadequate mixing, they can produce cracking, crazing, pinholes, delaminations

and voiding, which again is conducive to excessive moisture absorption. Probably

the most common problem encountered by users is the phenomena known as "pop

corning". It is caused by the rapid expansion of moisture within the encapsulant

during soldering. The moisture absorbed during storage and handling quickly

turns to steam producing sufficient pressures to literally blow the package

apart.

Typical examples of defects and anomalies are shown

in Figures 3 through 18.

Figure

3

C-SAM image of PEM with die-attach

delaminations (white area)

and poor material porosity causing fuzzy

image.

Figure

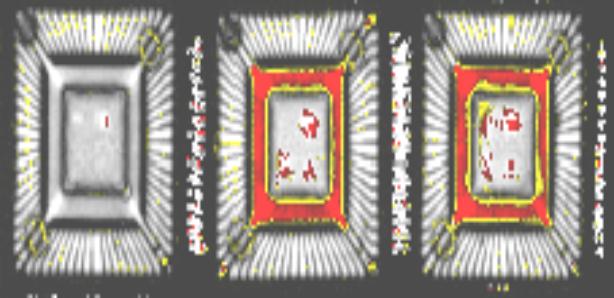

4

C-SAM images of PEM with delaminations

(Red area)

Figure 5

C-SAM images of PEMs.

Top images show

delaminations (Red area).

Bottom images show porosity in–texture appearance

is mottled.

Figure 6

C-SAM image of

PEM with poor die-attach (Red area)

and delaminations (Yellow/Red area)

Figure 7

C-SAM image of

PEM with poor die-attach.

Appears voided (Red area) and material has

excessive porosity causing fuzzy image.

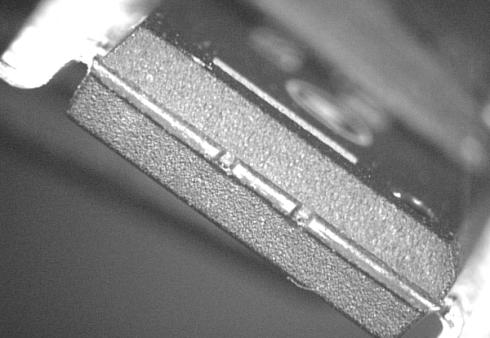

Figure 8

Construction

analysis photo of PEM.

Wire-bond displacement weakening bond causing latent

dis-bond failure.

Figure 9

C-SAM image of

PEM. “Pop-corning” effect

caused damaged corner from vapor phase solder

re-flow overheating.

Figure 10

Construction

analysis Photo of PEM. “Pop-Corning” effect

caused crack in plastic from

vapor phase solder re-flow overheating.

Figure 11

SEM photo of PEM. Contamination - Residue from

halogen presence in package.

Cause latent defect by accelerating corrosion

and weakening bond.

Figure 12

Photo of PEM

following Salt Spray test. Failures from excessive lead damage.

Caused by

Salt Spray.

Figure 13

Photo of PEM. Loss of seal integrity

at leadframe tabs of PEM.

Allowed moisture/salt ingression during salt

spray

Test. Accelerated corrosion latent defect.

Figure 14

C-SAM image of

PEMs.

Salt ingression into PEM following Salt Spray test. Cause latent

corrosion defect.

Same PEM as Figure 11.

Figure 15

SEM photo of

PEM with Kirkendall Voiding (Purple Plague)

Figure 16

SEM photo of

PEM with internal dendritic growth

Figure 17

C-SAM images

of PEMs with poor die-paddle attachment.

Left images are initial

scans.

Center images are following pre-conditioning.

Right images are

following 50 hours of HAST.

Figure 18

C-SAM images

of PEMs with poor Die-Attach.

Left images are initial scans.

Center

images are following pre-conditioning.

Right images are following 50 hours

of HAST.