System Acceptance and Operational Readiness Leadership Area:

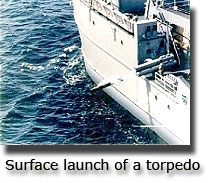

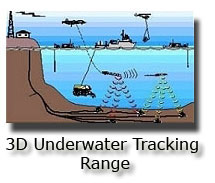

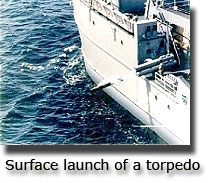

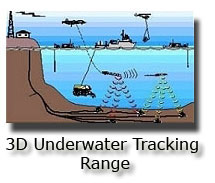

- Full spectrum undersea warfare test & evaluation and research & development testing

- Developmental testing

- Operational testing

- Production acceptance testing (proofing)

- In-service testing for performance verification

|

|

|

In-Service Engineering Integrated

Logistics Support:

- Submarine Systems

- Torpedoes and Targets

- Carrier Tactical Support Center

- Fleet Training Systems

- Obsolescence Management

|

We provide life-cycle support of Fleet deployed systems. Systems supportability includes engineering and logistics for products, services, and processes introduced in the Fleet. We focus on increased system capability, reliability, effectiveness, efficiency, availability and ease of maintenance; with the goal of reducing Navy costs of ownership and operation. We provide obsolescence management and technology road mapping support for a variety of systems through the Obsolescence Management Information System.

|

|

Maintenance Engineering & Industrial Operations Leadership Area

- Fully certified heavyweight torpedo intermediate maintenance activity

- Only fully certified lightweight torpedo intermediate maintenance activity

- USW weapon and combat systems depot

- Mine depot maintenance

- Leading edge fabrication technology

- Rapid prototyping and repair technology development

- Custom engineering solutions/obsolescence resolution

- Processes and permits for environmentally hazardous materials

|

|

We exploit leading-edge industrial technology and custom engineered solutions to mitigate the effects of obsolescence, improve reliability, and support the R&D community in prototype development and testing. We reestablish and maintain supply availability for a variety of systems and components through reverse engineering, depot repair, and prototyping & fabrication technologies. We focus solutions on improving performance, reducing required maintenance, reducing testing required for new product acceptance, and minimizing the effect of any design changes on surrounding equipment.

|